- Metrology - Laboratory

- Inspection and Monitoring

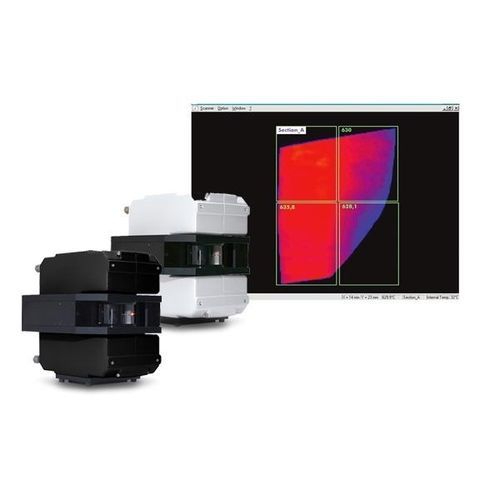

- Camera for the glass industry

- Fluke Process Instruments

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Imager for the glass industry GSmonitoringthermal imaginginfrared

Add to favorites

Compare this product

Characteristics

- Applications

- for the glass industry

- Function

- monitoring, thermal imaging

- Spectrum

- infrared

- Interface

- Ethernet

- Resolution level

- HD

- Other characteristics

- high-speed, line-scan, fixed

Description

Raytek GS150 thermal imaging systems enable automated quality control in glass bending, forming, annealing, and tempering processes.

The GS150LE variant is especially designed for Low-E (low emissivity) glass / one-side coated flat glass. It features automatic emissivity correction.

The systems are based on the Raytek MP150 infrared line scanner, which has a max. resolution of 1024 points per line, a max. 150 Hz scanning frequency, and an up to 90° wide field of view.

SYSTEM PROPERTIES

• Automated temperature monitoring

• Visualization on PC

• Ethernet TCP/IP interface integrated in the line scanning system

• PC-independent alarm output

• PC-independent analog outputs 3 x 4 – 20mA

BENEFITS

• Improve profitability and product quality

• Reduce set-up time

• Detect defects quickly

• Automate quality monitoring for ISO9000

• Reduce scrap

• Efficiently manage the heat balance in the oven

• Automatically adjust the emissivity value when changing glass types or coatings

VIDEO

Related Searches

- Digital camera module

- Visible camera system

- Datalogger

- Industrial camera system

- Infrared imager

- Surveillance camera

- Temperature data logger

- Waterproof camera system

- Detection imager

- USB data logger

- Thermal camera

- High-definition camera

- Robust camera

- Wireless datalogger

- High-speed camera system

- Datalogger without display

- IR camera system

- Battery-powered datalogger

- Power-over-Ethernet camera

- Monitoring data logger

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.