Gas blowing evaporator processgas

Add to favorites

Compare this product

Characteristics

- Type

- gas blowing

- Laboratory/process

- process

- Applications

- gas

Description

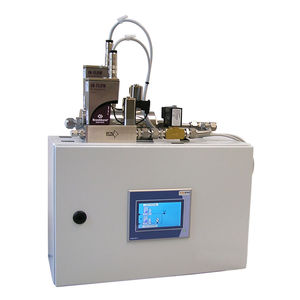

Evaporator systems from Flusys mix two or more gaseous components together. The first step involves transferring liquids into the vapour phase. Depending on the application, they are based on a direct evaporator or on an evaporator system based on carrier gas.

The gaseous components are then mixed and dosed in a controlled manner.

These requirements are typical for applications such as the following:

• screenshot evaporation system

• Targeted humidification of process gases for process technology

• Plug & Play vapour and precursor dosing units for low or high temperatures

• Production of calibration gases for testing gas analysers

• Evaporation of liquid mixtures for the operation of fuel cells

• Testing equipment for catalytic converters

• Evaporation of liquid reagents for coating a wide variety of materials

Monitoring and control tasks are performed by the software and visualisation modules. These are optimised in terms of hardware according to your requirements to come up with a customised total solution. With all Flusys systems the full range of control levels, from manual right up to fully automated, is possible.

A mixing or re-dosing unit can be integrated into the evaporator systems, e.g. to generate any composition of the mixture that you desire.

Another option is combination with storage tanks for the stockpiling and pressurisation of liquids.

One upgrade option is for temperature control of the subsequent process gas feed

Catalogs

No catalogs are available for this product.

See all of FLUSYS GmbH‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.