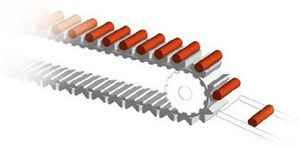

Toothed belt neoprene®coated

Add to favorites

Compare this product

Characteristics

- Type

- toothed

- Material

- neoprene®

- Other characteristics

- coated

Description

Many synchronized conveying processes may include some form of product folding, gluing, laminating, or labeling. We produce several variations of silicone and urethane release coatings that are applied to the belt surface to help eliminate the possibility of belt contamination. Typically vacuum conveyors are used with perforated timing belts. The vacuum, combined with our coating, can create the desired positive control of the product. The coating process allows us the flexibility of coating many different substrates, including urethane and neoprene timing belts, regardless of the belt width or length.

Catalogs

No catalogs are available for this product.

See all of F.N. Sheppard‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.