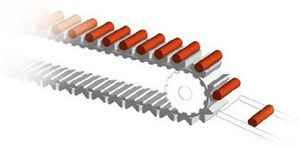

Toothed belt urethanefor conveyor rollers

Add to favorites

Compare this product

Characteristics

- Type

- toothed

- Material

- urethane

- Product applications

- for conveyor rollers

Description

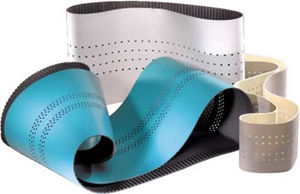

Reasons and Applications for Using V-Guide Tracking

Where pulley flanges can not be used or may interfere with products being conveyed

Conveyors with long center distance where true tracking is critical

Side loading or unloading applications

Where the belt runs on its edge in a vertical position instead of lying flat on a conveyor surface

Design Considerations

When a V-guide is added to the belt it can effect the flexibility which in turn effects the minimum pulley diameter. Modifications to the V-guide can be done to improve the flexibility, such as notching. Various size V-guides can be applied. Typically the V-guide is placed on the bottom center of the belt. It can also be positioned off-center, or combination V-guides can be used on wide belts. There should be clearance between the V-guide and pulley or slider bed groove. See drawings and chart below.

Catalogs

No catalogs are available for this product.

See all of F.N. Sheppard‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.