- Metrology - Laboratory

- Analytical Instrumentation

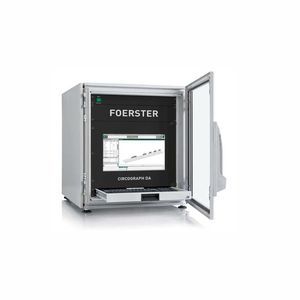

- Foerster Instruments

Crack detection detection system

Add to favorites

Compare this product

Characteristics

- Applications

- crack detection

Description

Induction thermography on components

Parts with complicated shapes have certain test areasthat are difficult or impossible to access with eddy currentprobes. Often, the only remaining method for crackdetection was magnetic particle inspection or penetrant testing.

With DEFECTOVISION CT - FOERSTER now offers a new, automatable solution for crack testing on components. The method of induction thermography is suitable for the examination of semi-finished products as well as complexly shaped components.

Your advantages at a glance

Fully automatable, contact-free, and non-destructive crackdetection

Suitable for open cracks, pores, heat treatment cracks,forging laps, welding defects, etc.

Can be used on rough, uneven surfaces and surfacescoated with water or oil

Suitable for asymmetric geometries, concave profiles, and small test areas

Low heating required

Testing in less than 1 second

Catalogs

No catalogs are available for this product.

See all of Foerster Instruments‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.