Roller coating machine sigmaR2Rroll-to-rollcontinuousslot-die

Add to favorites

Compare this product

Characteristics

- Options

- roller, roll-to-roll, continuous, slot-die

- Applications

- optical, high precision

Description

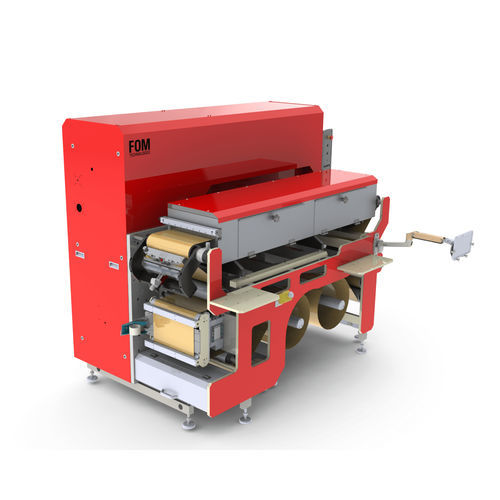

The FOM sigmaR2R is a lab-size roll-to-roll slot-die coating machine. It consists of unwind, rewind, 2-zone oven, and adjustable slot-die positioning around the coating roll. Components are operated from one integrated control system for easy customization. The FOM sigmaR2R is a continuous non-contact coater suitable to prepare uniform films for R&D and industrial batch production. It is the ideal manufacturing equipment for slurry drying processes of electrode coating.

Precision sheet coating machine made from high precision, certified industrial components

Up to 13” (350 mm) industry-standard web width.

Coating roller diameter of 100 mm

Custom width slot-die coating heads up to 350 mm width

Multiple full-width or stripe-pattern slot-die coating head

Single face continuous coating

Horizontal single pass hot air or IR combination oven (1.8 m oven)

Application foil e.g. Aluminum, Copper, plastic, paper

Dimensions: 2400 x 1550 x 1820 mm (L x W x H)

Compact R2R slot-die coating system

The FOM sigmaR2R is ideal for scaling up research-related and small production batches that require a thermal step post roll to roll web coating used in among others photovoltaics, optical coatings, batteries, fuel cells, and pharma related applications.

Coating & printing methods

The FOM sigmaR2R with optional continuous pumping of ink/slurry capabilities, facilitates the integration of multiple coating and printing methods into the machine frame, for example, slot-die coating and flexographic printing. Designed to handle a wide range of substrates it is currently running with carbon fiber tows, multiple plastics, paper, metal foils, and flexible glass.

Catalogs

FOM sigmaR2R

1 Pages

Related Searches

- Coating machine

- Automated coating machine

- Coating machine for pharmaceutical applications

- Roller coating machine

- Laboratory coating machine

- Optical coating machine

- Continuous coating machine

- High precision coating machine

- Slot-die coating machine

- Plastic film coating machine

- Conductive film coating machine

- Battery coating machine

- Solar cell coating machine

- Battery research coating machine

- Membrane coating coating machine

- Smart material coating machine

- Conductive foil coating machine

- Additive manufacturing coating machine

- Coating machine for photovoltaic applications

- Sensor coating machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.