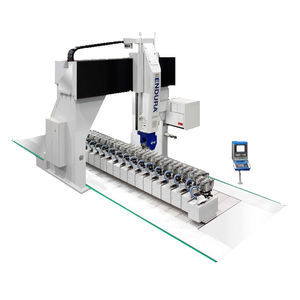

Gantry CNC milling machine ENDURA® 600LINEAR series5-axisuniversalfor aluminum

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- universal

- Structure

- gantry

- Machined material

- for aluminum, for composites, for stone

- Spindle mount

- HSK-63-A

- Applications

- for large workpieces

- Other characteristics

- HSC, with linear motor, with automatic tool changer

- X travel

Max.: 30,000 mm

(1,181.1 in)Min.: 5,000 mm

(196.85 in)- Y travel

2,800 mm, 3,500 mm

(110.24 in, 137.8 in)- Z travel

1,500 mm, 2,000 mm, 2,200 mm, 2,300 mm

(59.06 in, 78.74 in, 86.61 in, 90.55 in)- Rotational speed

24,000 rpm, 30,000 rpm

(150,796 rad.min-1, 188,496 rad.min-1)- Power

Max.: 45 kW

(61.18 hp)Min.: 20 kW

(27.19 hp)- Work feed X-axis

Max.: 65,000 mm/min

(43 in/s)Min.: 5 mm/min

(0 in/s)- Work feed Y-axis

Max.: 65,000 mm/min

(43 in/s)Min.: 5 mm/min

(0 in/s)- Positioning accuracy

0.015 mm, 0.02 mm, 0.03 mm

(0.00059 in, 0.00079 in, 0.00118 in)

Description

State-of-the-art linear drives gantry milling machine in portal design with 5 CNC-controlled simultaneous axes, particularly suitable for the efficient 5-sided finishing of workpieces made of clay, plastic, composite materials (CFRP, GFRP), model building block material (Ureol) and the HSC machining of aluminum.

The ENDURA® 600LINEAR gantry milling machine is equipped with linear motor drive technology, which has especially established for high-speed machining of large workpieces. Acceleration values of up to 3.0 m/sec² classify this series in the category of high-speed milling machines.

FEATURES, TECHNOLOGY AND EQUIPMENT:

Highly dynamic portal milling machine in overhead GANTRY design:

Overhead travelling portal in X-direction.

Design of the Machine:

Side walls (X-axis), cross slide, portal (Y-axis) and walking beam (Z-axis) are designed as a solid, stress-relief annealed welded steel structure.

Drive technology of linear axes

Water-cooled linear motors in the linear axes (X, Y and Z), X-axis configured as GANTRY-axis pair.

Direct measuring systems:

The linear and rotary axes are equipped with direct measuring systems.

Z-axis weight compensation:

Highly dynamic pneumatic cylinders support the Z-axis drive.

Safety system of linear axes:

The linear axes are equipped with a safety system that can decelerate and hold the axes safely in the event of a loss of voltage.

Linear axes guides:

The linear axes are equipped with hardened and ground, backlash-free pre-tensioned guide elements.

ADVANTAGES AT A GLANCE.

Very spacious machining area

Loading at ground level

Optimal dust extraction and chip conveyor concepts

Direct drives in all axes (linear and torque motors)

Catalogs

Related Searches

- CNC milling machine

- Vertical CNC milling machine

- 3-axis CNC milling machine

- Bridge CNC milling machine

- Precision CNC milling machine

- Swiveling-spindle CNC milling machine

- 5-axis CNC milling machine

- High-precision CNC milling machine

- Aluminum CNC milling machine

- Rigid CNC milling machine

- Compact CNC milling machine

- CNC milling machine with pallet changer

- Composite CNC milling machine

- Column type CNC milling machine

- High-speed CNC milling machine

- High-rigidity CNC milling machine

- Aluminum profile CNC milling machine

- Traveling-column CNC milling machine

- Profile CNC milling machine

- HSC CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.