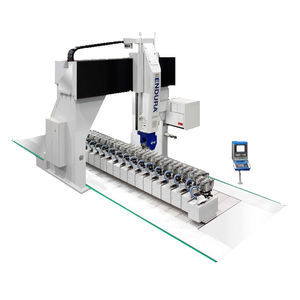

Compact CNC milling machine ENDURA® 700LINEAR series5-axisuniversalgantry

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- universal

- Structure

- gantry

- Machined material

- for aluminum, for steel, for cast iron, for composites, for stone

- Spindle mount

- HSK-63-A

- Applications

- for large workpieces

- Other characteristics

- compact, rigid, HSC, with linear motor, direct-drive

- X travel

1,500 mm, 2,200 mm, 5,500 mm

(59.06 in, 86.61 in, 216.54 in)- Y travel

2,000 mm, 2,800 mm, 3,500 mm

(78.74 in, 110.24 in, 137.8 in)- Z travel

1,200 mm, 1,500 mm

(47.24 in, 59.06 in)- Rotational speed

Max.: 30,000 rpm

(188,496 rad.min-1)Min.: 15,000 rpm

(94,248 rad.min-1)- Power

Max.: 70 kW

(95.17 hp)Min.: 20 kW

(27.19 hp)- Work feed X-axis

Max.: 90,000 mm/min

(59 in/s)Min.: 5 mm/min

(0 in/s)- Work feed Y-axis

Max.: 90,000 mm/min

(59 in/s)Min.: 5 mm/min

(0 in/s)- Positioning accuracy

0.015 mm

(0.00059 in)

Description

The ENDURA® 700LINEAR is a state-of-the-art 5-axis milling machine in compact gantry design with linear motor drive technology and 5 CNC-controlled simultaneous axes. The machine tool is particularly suitable for the efficient 5-sided finishing of workpieces made of plastics, composite materials (CFRP, GFRP), model building block materials (Ureol) and aluminum, as well as for the HSC machining of cast iron and steel materials.

The compact 5-axis milling machine ENDURA® 700LINEAR is characterized by high structural rigidity, features maximum dynamics and achieves highest accuracies. These properties result in optimum motion control and maximum productivity. Despite its compact design and small footprint, the 5-axis milling machine provides a large machining area.

The machine tool can also be set up without a foundation. With an acceleration of up to 5 m/sec², the FOOKE ENDURA® 700LINEAR is one of the most advanced high-speed milling machines.

FEATURES, TECHNOLOGY AND EQUIPMENT:

Highly dynamic GANTRY high-bed tool milling machine in compact design:

Portal moving in X-direction.

Design of the machine:

Machine bed made of solid cast iron, side walls (X-axis), cross slide and gantry

(Y axis) as welded steel construction, walking beam (Z axis) made of cast iron.

No foundation required:

Due to the inherently rigid machine bed, a standard industrial floor, approx. 300 mm thick, steel-reinforced, is sufficient for the installation; a special foundation, is not required. The machine is set up and aligned by fixators bolted to the hall floor.

Drive technology of linear axes:

Water-cooled linear motors in the linear axes (X, Y and Z), X axis designed as a GANTRY axis pair.

Catalogs

No catalogs are available for this product.

See all of FOOKE GmbH‘s catalogsRelated Searches

- CNC milling machine

- Vertical CNC milling machine

- 3-axis CNC milling machine

- Bridge CNC milling machine

- Precision CNC milling machine

- Swiveling-spindle CNC milling machine

- 5-axis CNC milling machine

- High-precision CNC milling machine

- Aluminum CNC milling machine

- Rigid CNC milling machine

- Compact CNC milling machine

- CNC milling machine with pallet changer

- Composite CNC milling machine

- Column type CNC milling machine

- High-speed CNC milling machine

- High-rigidity CNC milling machine

- Aluminum profile CNC milling machine

- Traveling-column CNC milling machine

- Profile CNC milling machine

- HSC CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.