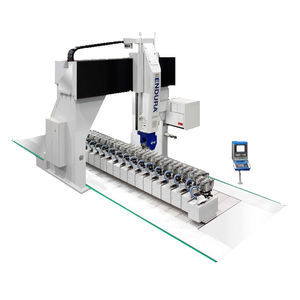

5-axis CNC milling machine ENDURA® 900LINEARuniversalgantryfor composites

Add to favorites

Compare this product

Characteristics

- Number of axes

- 5-axis

- Spindle orientation

- universal

- Structure

- gantry

- Machined material

- for composites

- Applications

- for sheet metal

- Other characteristics

- precision

- X travel

Max.: 30,000 mm

(1,181.1 in)Min.: 3,000 mm

(118.11 in)- Y travel

Max.: 4,000 mm

(157.48 in)Min.: 2,000 mm

(78.74 in)- Z travel

Max.: 3,000 mm

(118.11 in)Min.: 800 mm

(31.5 in)

Description

The latest generation in ENDURA® gantry milling machines has been designed with an overhead travel portal and is based on already extremely successful conventional ENDURA® products. The use of linear drive motors in our 5-axis milling machines eliminates the need for many mechanical elements such as gears, bearings, ball screws and rack gears, thereby enhancing structural rigidity, reliability and precision in particular.

Modular and fast – Gantry Milling Machine ENDURA®

Acceleration rates of up to 5 m/s², closed loop system reinforcements of 5 m/(min x mm) and a maximum deviation of 0.015 mm impressively reflect the power and precision of this 5-axis milling machine.

Up to 50% speed increase over conventional gantry milling machines, while ensuring highest levels of surface quality and accuracy. The Kv factor of 5-7 m/(min x mm) is a clear indicator for the machine's productivity; with conventional drive technology, the Kv factor is generally approximately 1-3 m/(min x mm).

FEATURES, TECHNOLOGY AND EQUIPMENT:

Highly dynamic overhead GANTRY tool milling machine:

Portal moving in X-direction.

Design of the machine:

Side walls (X-axis) in pylon column design with raised beds (welded steel structures, filled with highly damping special concrete), portal (Y-axis), cross slide and walking beam (Z-axis) as extremely rigid, yet weight-optimized welded steel construction.

Drive technology of linear axes:

Water-cooled linear motors in the linear axes (X, Y and Z), X-axis design as GANTRY axes pair.

Catalogs

Related Searches

- CNC milling machine

- Vertical CNC milling machine

- 3-axis CNC milling machine

- Bridge CNC milling machine

- Precision CNC milling machine

- Swiveling-spindle CNC milling machine

- 5-axis CNC milling machine

- High-precision CNC milling machine

- Aluminum CNC milling machine

- Rigid CNC milling machine

- Compact CNC milling machine

- CNC milling machine with pallet changer

- Composite CNC milling machine

- Column type CNC milling machine

- High-speed CNC milling machine

- High-rigidity CNC milling machine

- Aluminum profile CNC milling machine

- Traveling-column CNC milling machine

- Profile CNC milling machine

- HSC CNC milling machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.