- Power Transmission - Mechanical components

- Mechanical Transmission

- Flat belt

- Forbo Siegling GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

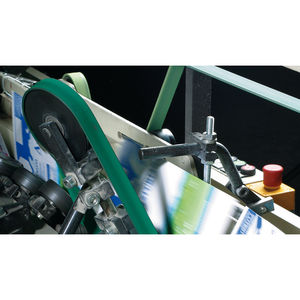

Flat belt rubberaramidfor conveyor rollers

Add to favorites

Compare this product

Characteristics

- Type

- flat

- Material

- rubber, aramid

- Product applications

- for conveyor rollers

- Other characteristics

- friction

Description

Siegling Extremultus live roller belts are energy-saving, durable components of driven live rollers. The quality and performance of the belts determine how quickly and reliably items our customers’ items are distributed. The belt’s tension member plays a key role in this process. Today’s standard is polyester fabric (E). But polyamide sheet (P) or aramide fabric (A) are also used. The tension member is embedded in a thermoplastic intermediate layer.

Rubber elastomer or urethane coat the two friction layers, which are the top face of the belt (towards the roller) and the underside of the belt (towards the drive and in some cases to the idler roller). The combination of tension member and coating lends the belt its special characteristics – tailored to conveyor type and purpose.

The splice requires no extra adhesives (in the Aramid and Polyester line) and can be made quickly, easily and cleanly on site.

Catalogs

No catalogs are available for this product.

See all of Forbo Siegling GmbH‘s catalogsRelated Searches

- Forbo transmission belt

- Industrial power transmission belt

- Rubber power transmission belt

- Plastic strip

- Forbo sturdy belt

- PU belt

- Synchronous power transmission belt

- Forbo flat belt

- High-performance power transmission belt

- Forbo abrasion-resistant belt

- Machine power transmission belt

- Polyester belt

- Belt for the food industry

- Low-noise power transmission belt

- High-power power transmission belt

- Friction power transmission belt

- Conveyor roller power transmission belt

- Aramid belt

- Strip strip

- Custom power transmission belt

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.