- Power Transmission - Mechanical components

- Mechanical Transmission

- Flat belt

- Forbo Siegling GmbH

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Flat belt rubberfrictionanti-static

Add to favorites

Compare this product

Characteristics

- Type

- flat

- Material

- rubber

- Other characteristics

- friction, anti-static, low-noise, abrasion-resistant

Description

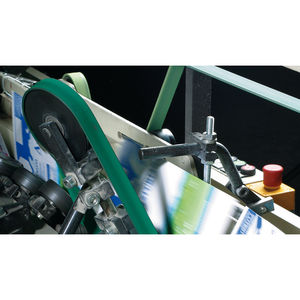

Siegling Extremultus tangential belts have been optimized to suit the diverse range of yarn-manufacturing processes and different drive shapes. They play a major role in ensuring consistently high yarn quality and efficient production due to the following characteristics:

superior abrasion-resistant coatings made of elastomer G or polyurethane with constant friction coefficients and long service lives;

optimized surface pattern for the spindle and motor side;

less belt creep and excellent levels of power transmission;

energy-efficient polyester or aramide tension members;

polyamide sheet tension members with good damping characteristics for high levels of effective pull;

low-noise and low-vibration operation;

antistatic finishes.

Siegling Extremultus tangential belts are supplied as roll material, prepared for splicing or have already been spliced. With our splicing methods, homogeneous, reliable splices can be made efficiently while belts are still on the machinery.

Catalogs

No catalogs are available for this product.

See all of Forbo Siegling GmbH‘s catalogsRelated Searches

- Forbo transmission belt

- Industrial power transmission belt

- Rubber power transmission belt

- Plastic strip

- Forbo sturdy belt

- PU belt

- Synchronous power transmission belt

- Forbo flat belt

- High-performance power transmission belt

- Forbo abrasion-resistant belt

- Machine power transmission belt

- Polyester belt

- Belt for the food industry

- Low-noise power transmission belt

- High-power power transmission belt

- Friction power transmission belt

- Conveyor roller power transmission belt

- Aramid belt

- Strip strip

- Custom power transmission belt

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.