- Products

- Cyanoacrylate fuming chamber

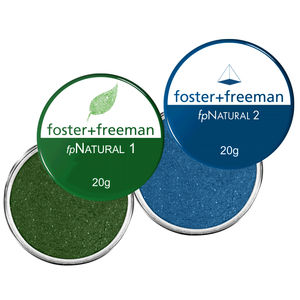

- Foster & Freeman

Cyanoacrylate fuming chamber RECOVER laboratoryforensic

Add to favorites

Compare this product

Characteristics

- Type

- cyanoacrylate

- Applications

- laboratory, forensic

Description

a cutting-edge chemical vapor fuming process to develop fingerprints on a range of difficult surfaces including those that have been exposed to extreme heat (discharged bullet casings, for example) and items that have been washed ‘clean’ in an attempt to prevent identification.

Fired Ammunition

Fired bullet cartridges are notoriously difficult to retrieve ‘usable’ prints from. RECOVER can yield fingerprints of incredibly high quality.

IED Fragments

The original RECOVER application, prints can be visualized on metals exposed to extreme heat, including Improvised Explosive Device (IED) fragments.

Washed Items

Even when an item of evidence has been washed clean, or submerged for an extended period of time, RECOVER can still retrieve identifiable prints.

Discovered at Loughborough University, developed with the backing and support of the UK Defence Science and Technology Laboratory (dstl), and now, refined by foster+freeman, RECOVER LFT fingerprint technology represents a fantastic example of collaborative working to achieve innovation that will help the police and security services to identify criminals and link them to their crimes.

RECOVER semi-automates the complex chemistry required to produce consistently high-quality fingerprints on untreated or cyanoacrylate-fumed items of evidence. Designed, engineered, and refined to provide a simple, low-maintenance solution, RECOVER contains all of the hardware and software components required for fingermark development, within a compact laboratory system.

Motorized Lid

Offers adjustable capacity

Operated via the touchscreen, enables development chambers of varying capacity to be used.

VIDEO

Catalogs

RECOVER

8 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.