- Products

- Catalogs

- News & Trends

- Exhibitions

Stationary turbo-compressor TCH Seriespower generationturbine

Add to favorites

Compare this product

Characteristics

- Type

- stationary

- Applications

- power generation

- Other characteristics

- turbine

- Pressure

40 bar

(580 psi)

Description

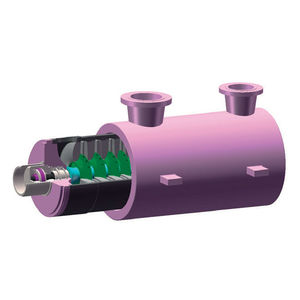

TCH process compressors are horizontally split type, meaning that casing is made by two halves, jointed on a plane parallel to the rotor axis.

Low and medium pressure applications (up to 40 bar) are typical for this design. This configuration allows easier access to all internals for inspection and maintenance, as most of the cases piping nozzles are located on the bottom half of the casing, and just unbolting the joint and lifting the upper casing, rotor and other inner components can be serviced, without removing process and auxiliary piping. TCH serie compressors, API617 compliant, can be arranged in a variety of flow path configurations, implementing one to ten impellers, depending on the required head. When interstage cooling is not necessary, the arrangement is usually a straight-through (inline) configuration, with one single body and one flowpath.

When intercooling is required, machine configuration typically results into two-section compressor in either an inline (compound) or back-to-back arrangement, with one single body and two flowpaths. Also a double-flow configuration is available for high-flow/low-head applications, with one single body and two inlet flowpaths converging into a single outlet.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.