- Products

- Catalogs

- News & Trends

- Exhibitions

Compact turbo-compressor TCB Seriesstationarypower generationturbine

Add to favorites

Compare this product

Characteristics

- Type

- compact, stationary

- Applications

- power generation

- Other characteristics

- turbine

- Pressure

800 bar

(11,603 psi)

Description

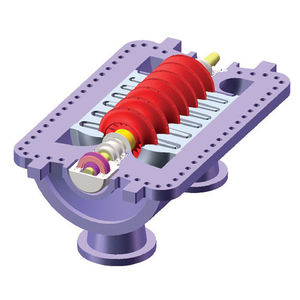

TCB process compressors are vertically split type, with end covers secured to the main body by means of bolting or shear rings. Process flanges are usually fitted on the upper region of the cylinder, inline or slanted. This type of machine is usually selected for High Pressure (over 40 bar) and for critical services applications (hydrogen mixtures, toxic gases).

The rotor and stationary internals are assembled as a cylindrical inner bundle. By removing the end cover, this bundle is inserted or removed axially through one end of the outer casing.

Normally more compact than TCH machines, TCB barrel compressors are fitted with 2 to 9 impellers per casing. Both journal and thrust bearings are of the tilting-pad type. Dry gas type mechanical seals are the standard choice for shaft-end, while the interstage seals are of the labyrinth type.

While inspection & maintenance to rotor and diaphragms require the inner bundle to be removed, bearings as well as shaft-end seals can be accessed directly from external, making these operations easier.

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.