- Products

- Dimensional measurement device

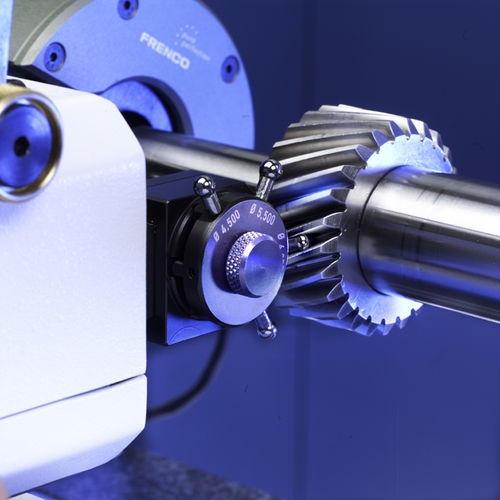

- Frenco GmbH

Profiled parts dimensional measurement device RK

Add to favorites

Compare this product

Characteristics

- Options and accessories

- profiled parts

Description

The URM-K is a rotation inspection instrument engineered by Frenco. It is suitable for inspecting profiled components, such as profiled shafts.

The instrument is placed on the shop floor next to the production machine. This location ensures a fast and reliable sampling inspection. The equipment also inspects diameters for size, concentricity, and roundness. It determines locational deviations through gear, diameter and surface referencing.

The URM-K is flexible enough for use with a variety of workpiece types. It is constructed in a robust design, and made using wear-resistant materials to ensure low maintenance costs. The unit features a documentation of the measuring results for process control. In addition, it can be operated manually, semi-automatically or fully-automatically.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.