- Products

- Catalogs

- News & Trends

- Exhibitions

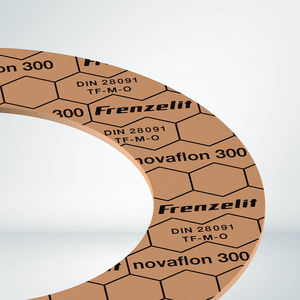

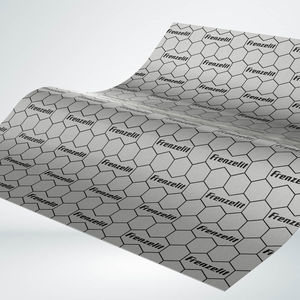

Glass gasket sheet novaflon® 100PTFEstick

Add to favorites

Compare this product

Characteristics

- Material

- glass, PTFE

- Product applications

- stick

Description

Modified PTFE with excellent adaptability

novaflon® 100 consists of structured PTFE and is filled with hollow glass microspheres. The material is universally resistant to nearly all chemicals throughout the entire pH range. novaflon® 100 is perfect for use in acids above 85 °C. Optimal filler integration gives the material low basic porosity and enables it to achieve a very low leakage rate, even with already low surface pressure.

novaflon® 100 exhibits high compressibility and perfectly adapts to the respective sealing surface. This enables novaflon® 100 to easily compensate for light damage to the sealing surfaces and provide a reliable seal even with lower surface pressure. novaflon® 100 is therefore ideal for use in GFRP flanges and enameled flanges of pipes and apparatus.

Creep properties have been optimized in novaflon® 100, thus the gasket exhibits minimal hot creep behavior. In turn, this results in good residual stress.

novaflon® 100 gaskets can be produced with all conventional processing techniques. novaflon® 100 is quick and simple to install and, thanks to their excellent anti-stick properties, the gaskets can be removed again after use without leaving any residues.

Catalogs

No catalogs are available for this product.

See all of Frenzelit‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.