- Products

- Catalogs

- News & Trends

- Exhibitions

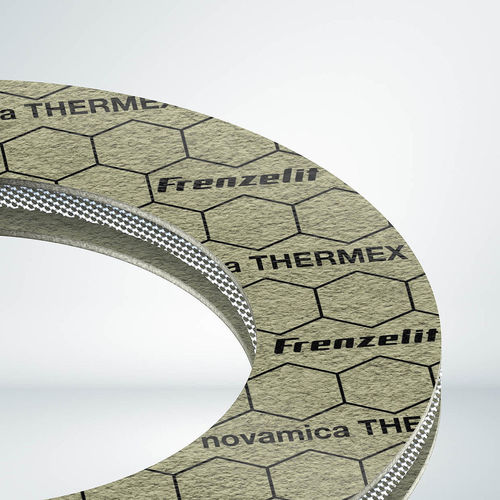

Composite material gasket sheet novamica® THERMEX metalstainless steelmica

Add to favorites

Compare this product

Characteristics

- Material

- composite material, metal, stainless steel, mica, aramid

- Product applications

- exhaust, handling

- Temperature limit

1,000 °C

(1,832 °F)

Description

The novamica® product family is based on high-grade, optimized phlogopite mica, which is far superior to other types of mica in terms of temperature resistance. In combination with an effective binder system, novamica® opens up a variety of application possibilities in high temperature ranges. novamica® materials have excellent performance characteristics thanks to their extremely low binder content. novamica® enables reliable solutions for applications that cannot be not covered by conventional gasket materials.

novamica® gaskets have the following properties:

High chemical resistance – even against aggressive and corrosive media

Good thermal and electrical insulation properties

Incombustible (DNI = does not ignite – according to ASTM SAE J369 fire test)

Extremely low binder content guarantees long-term stability

novamica® products are not only suitable as conventional high-temperature gaskets but also as insulation materials or temperature-resistant compensation elements.

The gasket solution for the highest temperature loads

novamica® THERMEX combines the positive properties of optimized phlogopite mica with those of the expanded metal concept, like the way it is used for example in novaphit® SSTC. novamica® THERMEX is designed for use as a conventional gasket material in high temperatures. It is ideal for all sealing requirements in hot gas and exhaust applications (such as exhaust systems, turbochargers, etc.)

novamica® THERMEX is a composite material featuring a perfectly balanced binder system and proven expanded metal insert for internal strength and never-before-seen long-term sealing performance in high temperature ranges.

Catalogs

No catalogs are available for this product.

See all of Frenzelit‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.