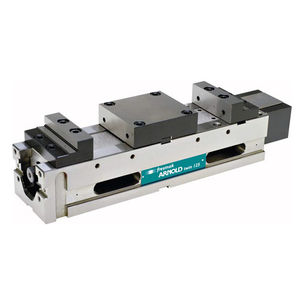

Machine tool vise 010 140 ARNOLD CLASSIC serieshydraulicspringrotary

Add to favorites

Compare this product

Characteristics

- Applications

- for machine tools

- Operation

- hydraulic

- Configuration

- spring, rotary

- Other characteristics

- high-pressure, automatic

- Max. clamping force

40 kN, 50 kN, 80 kN

Description

- Accuracy of 0.01 mm in clamping repeatability.

- Monoblock design avoids deformations due to high pressure and offers great rigidity and robustness.

- The force applied by the high pressure spindle is transmitted to the work-piece right in the centre of the clamping jaw.

- Large aperture up to 375 mm and 845 mm if the body is in two parts.

- Clamping force is 25/40/50/80 kN, depending on the model.

- ARNOLD CLASSIC spindles can be used independently from the vice as a power clamping element in a workholding set up.

- Designed to automate processes and robotize them.

- Fitted with a single acting oleo-dynamic spindle, with spring push-back effect.

- Rotary connection at the inlet and the outlet for oil.

- Automatic stroke for closing and opening up to 4 mm.

- Adjustable clamping force and directly proportional to oil pressure input (see manual).

- Two part straight vice option upon request.

- Common features page 32.

ELEMENTS REQUIRED

- Hydraulic unit or single acting 500 bar pneumo-hydraulic pump with vice unit connection hose, pressure control switch, safety valve integrated into the unit and ON-OFF switch.

- Pressure gauge.

VERSIONS

Standard

Clamping to the machine table can be achieved through the holes and the slots on the side of the vice.

It can be supplied with a rotary base.

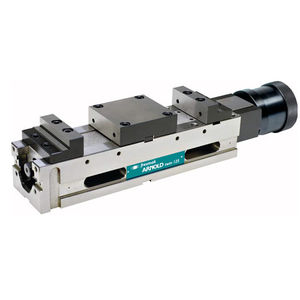

Straight

Its narrowness makes it easy for it to be placed jointly parallel to another vice, thereby allowing for a large clamping unit for large workpieces.

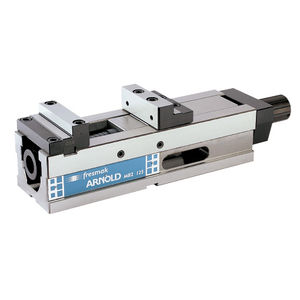

Two part straight

Ideal for large work-pieces.

It clamps the work-pieces on top of the guides or on top of the table.

An inner tie-rod joins both parts of the vice.

Catalogs

No catalogs are available for this product.

See all of Fresmak‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.