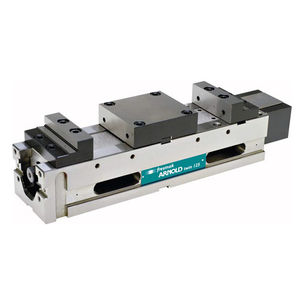

Machine tool vise 020 140 ARNOLD MAT serieshydraulichorizontalvertical

Add to favorites

Compare this product

Characteristics

- Applications

- for machine tools

- Operation

- hydraulic

- Configuration

- horizontal, vertical, spring

- Other characteristics

- high-pressure, automatic

- Max. clamping force

25 kN, 40 kN, 50 kN

Description

High pressure ARNOLD MAT vices maintain their length irrespective of the size of the part, for which they are especially ideal for machining centres (vertical and horizontal).

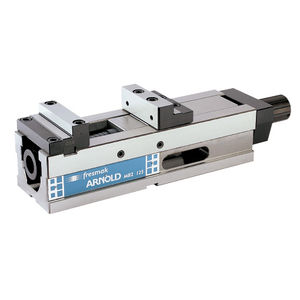

- Accuracy of 0.01 mm in clamping repeatability.

- Monoblock design avoids deformations due to high pressure and offers great rigidity and robustness.

- Ideal for working in horizontal and vertical machining centres.

- Grinding of all surfaces with a parallelism and perpendicularity of 0.02 mm.

- Possible working positions: supported on the base, on the side or on the head vertically.

- Side windows for quick cleaning of the inside of the vices.

- May be clamped to the table either by the four standard clamps supplied or by using four screws located in the body.

- Clamping force is 25/40/50 kN, depending on the model.

- Designed to automate processes and robotize them .

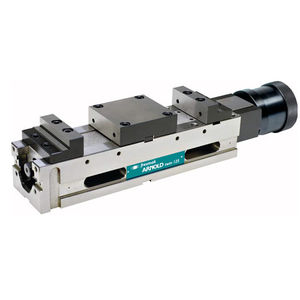

- Two clamping possibilities, either towards the fixed head or in reverse direction. Normal clamping is towards the fixed head.

- Fitted with a single acting oleo-dynamic spindle, with spring push-back effect.

- Rotary connection at the inlet and the outlet for oil.

- 4 mm. automatic stroke for closing and opening.

- Adjustable clamping force and directly proportional to oil pressure input (see manual).

TIPS FOR USE

- Should reverse clamping be needed, just place the spindle at the rear part of the fixed head, clamped by four screws. Then rotate the spindle shoe and the moveable jaw.

Catalogs

No catalogs are available for this product.

See all of Fresmak‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.