- Robotics - Automation - Industrial IT

- Automation

- Measurement control system

- Friedrich Vollmer Feinmessgerätebau GmbH

Measurement control system BFIflatness

Add to favorites

Compare this product

Characteristics

- Function

- measurement, flatness

Description

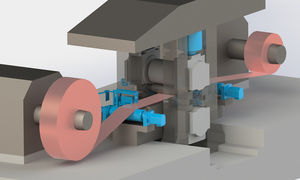

The BFI shapemeter rolls that we produce under licence from the VDEh-Betriebsforschungsinstitut (BFI) have a solid roll body with a homogeneous steel surface. They are normally installed instead of the existing deflector rolls.

For the measurement of wedge-shaped strip, Vollmer offers a special solution that is also based on the BFI patent. It ensures that the flatness of the strips is measured correctly even though transversal stresses are created in the strip during coiling.

Individual adaptation

With individually manufactured diameters between 200 and 500 mm it is possible to precisely replace the deflector rolls in practically all mills. The outer surface of the roll body is absolutely homogeneous and can be reground on all standard roll grinding machines.

The width of the measuring zones can be freely selected above 17 mm. The number of measuring zones that the roll should have is determined individually.

Vollmer supplies the shapemeter rolls with different surface finishes: Steel, chrome, tungsten carbide or plastic.

The principle - The technology in detail

The BFI measuring rolls use piezoelectric pressure gauges which – spread over the width of the strip – are installed in bores under the roll surface. They measure the strip tension distribution as the strip passes over the shapemeter roll.

Permanently reliable

The telemetric data transmission from the roll – without slip rings – ensures reliable and practically maintenance-free operation. The sensors can be replaced on site. The roll requires neither compressed air nor water.

Catalogs

BFI SHAPEMETER ROLL

2 Pages

Other Friedrich Vollmer Feinmessgerätebau GmbH products

Strip shape

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.