- Metrology - Laboratory

- Metrology and Test Equipment

- Diameter measuring instrument

- Friedrich Vollmer Feinmessgerätebau GmbH

Diameter measuring device VSLroundnesseccentricityprocess

Add to favorites

Compare this product

Characteristics

- Measured value

- diameter, roundness, eccentricity

- Applications

- process

- Other characteristics

- automatic

Description

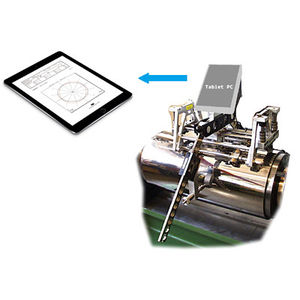

The gauges from the VSL Series measure the form, diameter, roundness and eccentricity of the rolls during the grinding process with very high precision. Form, radial run-out and eccentricity are measures with a precision of ± 1 µm.

If an interface is available, they communicate online with the controller of the roll grinding machine and thus enable even more cost-effective use of the grinding machine.

With the appropriate configuration, they measure the height and lateral alignment of the roll in the grinding machine before grinding, often enabling the set-up time to be significantly reduced.

Vollmer produces the automatic roll measuring gauges for both bench-mounted machines where the roll is moved along the grinding wheel and for support machines where the grinding wheel is moved along the rotating roll. Vollmer supplies the systems for a broad spectrum of roll diameters.

For back-up rolls that are ground in chocks, Vollmer offers the Side Shift option with which the gauge actively avoids the attachments at the ends of the rolls.

Vollmer also has special design for pressure rolls with deep and wide grooves in the surface.

Catalogs

No catalogs are available for this product.

See all of Friedrich Vollmer Feinmessgerätebau GmbH‘s catalogsOther Friedrich Vollmer Feinmessgerätebau GmbH products

Roll Measurement

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.