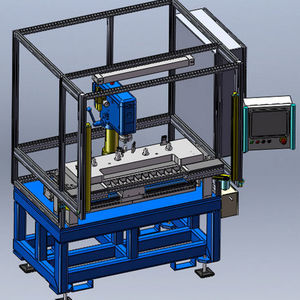

CNC riveting center automatic

Add to favorites

Compare this product

Characteristics

- Other characteristics

- CNC, automatic

Description

The CNC riveting machine with handling robot is a further innovation from the house of Friedrich. Due to its enhanced degree of automation it represents a new dimension in riveting technology. Its construction and properties are based on the proven design of the CNC riveting machines with indexing table. It is equipped with a Friedrich CNC control with extended user interface and process visualisation.

• 3 sizes

• indexing table ø 650/900/1200mm

• riveting areas from 280x180mm to 500x350mm

• coordinate system with recirculating ball screws

• electrically-operated rotary indexing table

with 2 or 4 fixed indexing stations and braking motor

• NC rotary table (optional)

• automatic tool changer

• C-shaped frames in different heights and projections

• freely programmable handling robot

• Friedrich CNC control with riveting process monitoring

• touchscreen panel 12” with Windows CE4.2 user interface

• adaptable sorting and feed stations

• compact design, thus little space required

• enhanced degree of automation

• cost reduction due to picking and placing operation in parallel with the primary processing time

• cost reduction by cycle time reduction

• menu navigation makes programming plain and simple

• each riveting programme can be assigned its own robot handling sequence.

Robots by Kuka, Adept, ABB, and Universal Robots can be used.

Catalogs

No catalogs are available for this product.

See all of D. Friedrich‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.