Radial riveting center CNChigh-speed

Add to favorites

Compare this product

Characteristics

- Type

- radial

- Other characteristics

- CNC, high-speed

Description

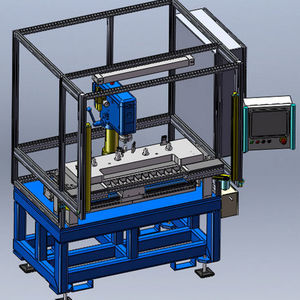

The CNC riveting module was developed in particular for use on special-purpose machines and in plant engineering. The base plate, coordinate axes, C-shaped frame and the riveting machine can be configured to match the installation situation they are intended for. The Friedrich CNC control with its touchscreen panel and a clearly laid out tabular structure is designed for easy programming.

- solid, torsion-resistant base plate with

mounting bores

- coordinate system with linear units and

recirculating ball screws

- riveting areas 180x280 mm to 350x500 mm

- digital high-speed drive with motion control

- C-shaped frames in different heights and projections

- pneumatically- or hydraulically-operated

radial point riveting machines can be used

- Friedrich CNC control with riveting process monitoring

- switchgear cabinet for individual installation

- various interfaces for data transfer

- can be used as single module or together with others

- can be integrated into special-purpose machines and manufacturing systems

- minimum distances between rivets can be achieved

- high movement speed, up to 400 mm/s

- high acceleration rate with high positioning accuracy

Catalogs

No catalogs are available for this product.

See all of D. Friedrich‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.