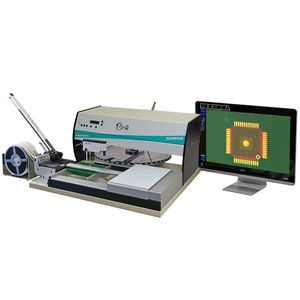

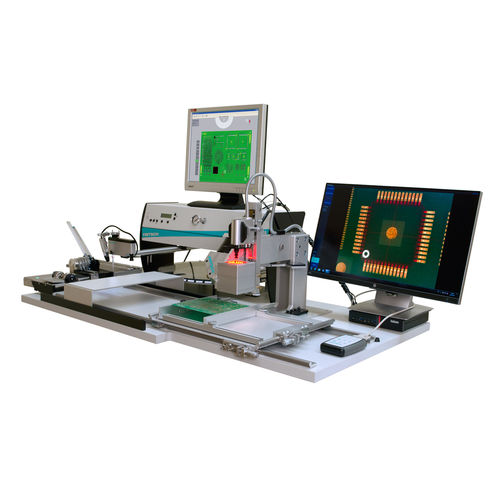

BGA pick-and-place system MP904SMTmanualvacuum

Add to favorites

Compare this product

Characteristics

- Applications

- for BGA, SMT

- Other characteristics

- manual, vacuum

Description

The universal assemblystationMP904 combines the easy and flexible operation of a manipulator with the high standards of exact placing of Fine-Pitch components.

The unrivalled smooth-running guide of the mounting head helps to place the SMDs accurately. When the pipette comes into contact with the components, the vacuum automatically switches itself on and when placing them, it switches off.

The specialised vision system allows the optimal placement of BGA and QFN components. The range of assembly elements starts by Chip 0201 and ends at Fine-Pitch and BGA.

To assemble prototypes and small series more quickly, a dispenser can be mounted to the assembly head. It can be used to dispense solder paste or glue on the circuit board.

The solid construction of the Handling Head insures highly precise placement of BGA and Fine Pitch Components. The specialised vision system allows two pictures to be viewed simultaneously. The PBC and the underside of the BGA can be observed. With the help of a Fine-Setting-table and micrometer screws both exposures can be adjusted exactly congruent. An easy and accurate placement of the components is assured.

The micrometer screws at the side of the FP904 allow a precise alignment of the component on the circuit board, in combination with the X / Y - table.

With a camera attached to the assembly head, you can view the whole Pick&Place process - magnified on a monitor.

Thus even the smallest parts like 0201 and 0402 can be placed exactly. Another benefit of the camera is the possible docu- mentation of the process by saving single picture frames to the harddisk of an attached PC.

VIDEO

Catalogs

Productline

20 Pages

Related Searches

- Stencil printer

- Soldering machine

- Reflow soldering machine

- Pick-and-place system

- Printed circuit soldering machine

- SMT pick-and-place system

- Electronic stencil printer

- Automatic pick-and-place system

- SMT stencil printer

- Solder paste stencil printer

- Semi-automatic stencil printer

- Manual stencil printer

- Modular pick-and-place system

- LED pick-and-place machine

- PC-controllable soldering oven

- Vacuum pick-and-place system

- BGA pick-and-place machine

- In-line pick-and-place machine

- Semi-automatic pick-and-place machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.