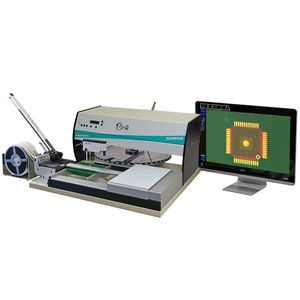

SMT pick-and-place machine SM902semi-automatic

Add to favorites

Compare this product

Characteristics

- Applications

- SMT

- Other characteristics

- semi-automatic

Description

Our semi-automatic manipulator SM902 eliminates wrong placements and relieves the user as reading the assembly plan isn't necessary anymore.

The pickup and place position for the next component is shown on the monitor. The user is guided through the whole project step by step.

For the SM902 the same options as for the LM901 are available. To further support the user, the SM902 can be upgraded step by step to the functionality of the SM902professional. This increases the assembly output even further.

To create new assembly projects with ease, a universal CAD data converter reads in existing CAD information for the SM902.

By this you stay flexible in the future.

If no CAD data is available, the needed placement positions can be teached in by hand.

To do this, each needed position is approached and approved to the System.

The offline software makes it possible to prepare all needed project data on a separate PC. The results can then be trans- ferred to the machine using a network or a storage device.

The movement direction to the next target position is additionally displayed by 4 LEDs on the assembly head.

The SM902 can by upgraded to the functionality of the SM902professional step-by-step (i.e. with LED feeder-display, automatic feeders etc.).

By this the user is further releafed and the placement output is increased.

To assemble prototypes and small series more quickly, a dispenser can be mounted to the assembly head. It can be used to dispense solder paste or glue on the circuit board.

With a camera attached to the assembly head, you can view the whole Pick&Place process - magnified on a monitor.

VIDEO

Catalogs

Productline

20 Pages

Related Searches

- Stencil printer

- Soldering machine

- Reflow soldering machine

- Pick-and-place system

- Printed circuit soldering machine

- SMT pick-and-place system

- Electronic stencil printer

- Automatic pick-and-place system

- SMT stencil printer

- Solder paste stencil printer

- Semi-automatic stencil printer

- Manual stencil printer

- Modular pick-and-place system

- LED pick-and-place machine

- PC-controllable soldering oven

- Vacuum pick-and-place system

- BGA pick-and-place machine

- In-line pick-and-place machine

- Semi-automatic pick-and-place machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.