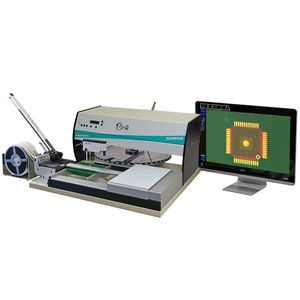

Manual pick-and-place system LM901for BGASMTmodular

Add to favorites

Compare this product

Characteristics

- Applications

- for BGA, SMT

- Other characteristics

- manual, modular

Description

The LM901 is the entry model of our modular-built systems. Besides the LM900 functionality, it can be extended with axis brakes, dispensers and optical support systems for component placing.

The LM901 supports the whole dispensing-/ Pick&Place - process, from supplying the solder paste or glue to placing standard, Fine-Pitch or BGA components.

The universal circuit board holder retains single- and double-sided boards safely using adjustable, elastic holding fingers (see picture above). Large circuit boards can be handled on demand.

If you need a custom circuit board holder, our developement department is pleased to realize this special task for you.

The unequalled guiding system of the assembly head results in comfortable and fatigue-free daily work. All of the control elements are arranged logically and ergonomically, which assists the user in the best possible way.

A relocatable hand-rest is already included in the standard version of the machines.

The assembly head is equipped with a patented constant-force trapezoidal spring. The spring tension is distributed equally over the total range of the Z-axis.

The whole assembly head is maintenance-free.

To assemble prototypes and small series more quickly, a dispenser can be mounted to the assembly head. It can be used to dispense solder paste or glue on the circuit board.

The X/Y locking device (fig.) ensures precision mounting. Individual movement axes can be locked. An automatic function independently locks the X and Y axes when the components are lowered or when placing a dispenser dot. This makes it particularly easy to place Melfs.

VIDEO

Catalogs

Productline

20 Pages

Related Searches

- Stencil printer

- Soldering machine

- Reflow soldering machine

- Pick-and-place system

- Printed circuit soldering machine

- SMT pick-and-place system

- Electronic stencil printer

- Automatic pick-and-place system

- SMT stencil printer

- Solder paste stencil printer

- Semi-automatic stencil printer

- Manual stencil printer

- Modular pick-and-place system

- LED pick-and-place machine

- PC-controllable soldering oven

- Vacuum pick-and-place system

- BGA pick-and-place machine

- In-line pick-and-place machine

- Semi-automatic pick-and-place machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.