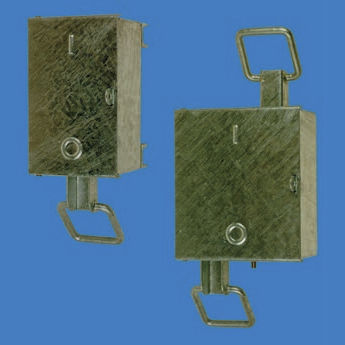

The outdoor motor actuators are in a aluminium housing (fig. 1), protection class IP 54 or in a stainless steel housing (fig. 2 – 4), protection class IP 65. The housing cover is screwed with A2 screws. Both housings are of modular designs, and contain control devices like control contactors, motor protection switches, control and signalling contacts as well as the wiring connected to the terminal strips. Through the modular design of the motor actuators, customer specific requirements such as mechanical or electric interlocking, actuators with key interlocking system or “on-site/remote operation” can be realized. For entering the control and record lines you will find two screw connections M20, M25 or M31,5.The outdoor actuator offers a vermin secure ventilation of the housing as well as a thermostatically controlled heating. The manual emergency operation works by means of a bevel gearing. A displacement of the bevel gearwheel for the reversal of the sense of rotation is not necessary any more as the rotating direction can be changed easily on the actuating rod which leads to the switch. Therefore, the electric connection is the same. Of course, the motor circuit is inevitably disconnected right before the crank is fixed to the square counter piece. A device in which a padlock can be hinged, prevents from unauthorized operation of the hand emergency actuator and opening of the cover. The fixing of the motor actuator is effected by means of four threaded bolts on the back side of the housing.