- Building - Construction

- Construction and Mining Equipment

- Truck wheel washer

- FRUTIGER Company AG

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

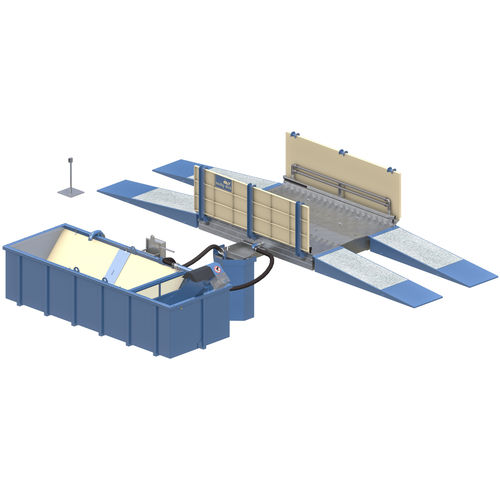

Truck wheel washer Flex 400 MC

Add to favorites

Compare this product

Characteristics

- Type

- for trucks

Description

The wheel washing systems of the Flex series were developed by our engineers specifically for the needs of the construction industry. The basic unit of the modular concept consists of a robust 158 inch long wash unit and a recycling tank. It can be combined with a scraper conveyor, a mobility package or a second basic unit to form eight different wheel washing systems that are

158 or 316 inch in length. All models can be installed quickly and impress thousands of operators around the world.

Function description

A truck drives slowly up the ramps into the wheel washing system. The vehicle identification sensor automatically triggers the

washing process. The specially coordinated nozzle system, consisting of a large number of bottom and side nozzles, then ensures the intensive cleaning of all tires and the entire chassis in one wheel rotation. Higher vehicle areas such as windows and

rear-view mirrors are not washed, so as to leave the driver’s field of vision clear. The kneading effect created by the angle profiles

gives the tire treads additional cleaning. The duration of the washing process can be freely selected using the timer relay in the

control cabinet, in accordance with the relevant operating conditions. The waste water runs via the return channel from the wash

unit to the side pump sump tank. From there it is pumped into the recycling tank by a MobyPump macerating pump. This is where

the washed-off solids settle out. The water is fed via the partition wall with sieve insert into the pump chamber. There it is recycled

for further spraying by a robust MobyPump immersion pump. The scraper conveyor conveys settled solids out of the recycling

tank

Catalogs

No catalogs are available for this product.

See all of FRUTIGER Company AG‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.