The Most Powerful nesting software to optimize progressive die nesting layout to improve material utilization and calculate costs

Drastic reduction of risk related to inaccurate material cost calculations; reduces supplier variation between estimate and actual costs from 25% to within 1-2%

Process 50 times more quotes than manual calculations

More accurate scrap estimates for material rebates

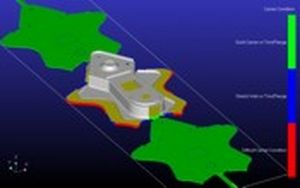

Provides optimized nesting layout for all possible processing layouts

FEATURES:

Produces fully optimized nesting layouts for 1-up, 2-up, and mirrored progressive die configurations

Constrains progression, coil width, and blank rotation to ensure the layout is compatible with manufacturing equipment

Calculates accurate cost per blank based on supplied input data and material utilization

Material cost calculation considers variations in thickness and coil width

Detailed documentation system produces HTML format reports

User input for distance between blanks, distance to edge of coil, carrier allowance and carrier width