- Robotics - Automation - Industrial IT

- Industrial Software

- Calculation software

- FTI Forming Technologies Incorporated

Engineering software COSTOPTIMIZER calculationcost estimation

Add to favorites

Compare this product

Characteristics

- Function

- engineering, calculation, cost estimation

Description

The Material Cost Reduction Tool for Estimators, Product and

Tool Engineers

The most accurate and speedy tool for RFQ generation; on average 24% of RFQs are late

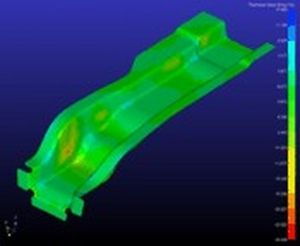

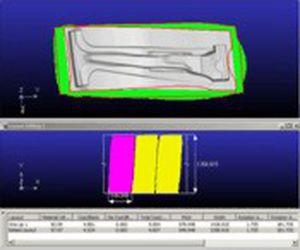

Accurate material cost calculation, in minutes, accounting for processing and tooling constraints on coil layouts

Identifies critical product and process design changes to yield a 5-15% material cost reduction

More than 70% productivity improvement in evaluating multiple costing scenarios

FEATURES:

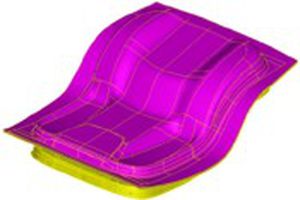

The ONLY Regenerative and Associative environment for fast and accurate blank generation, nest evaluation and material cost reductions; uses the most accurate blank development engine as well as the most accurate nesting engine

Simulates multiple costing scenarios in minutes, using a fully regenerative and associative environment

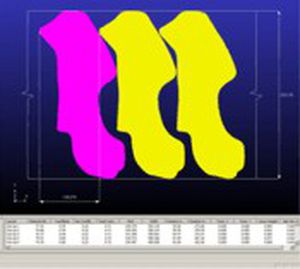

Produces fully optimized blanks and nesting layouts for cut-off dies, one-up, two-up, and mirrored nesting configuration

Constrains pitch, coil width, and blank rotation to ensure nest layout is compatible with your manufacturing equipment

Catalogs

Other FTI Forming Technologies Incorporated products

FormingSuite

Related Searches

- Analysis software solution

- Process software solution

- Computer-aided design software

- Real-time software solution

- Design software solution

- Simulation software

- Development software

- Engineering software

- Calculation software

- CAD/CAM software

- SolidWorks software

- Nesting software

- PLM software

- CATIA V5 software

- Cost estimation software

- Schema design software

- Stamping simulation software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.