- Robotics - Automation - Industrial IT

- Industrial Software

- Nesting software

- FTI Forming Technologies Incorporated

Nesting software BLANKNESTprocess

Add to favorites

Compare this product

Characteristics

- Function

- nesting

- Applications

- process

Description

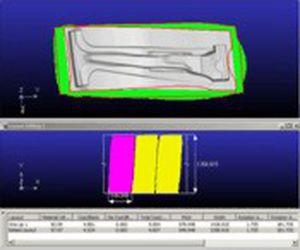

The Most Trusted Tool to determine optimal material usage through geometric nesting of blanks

Drastic reduction of risk related to inaccurate material cost calculations; reduces supplier variation between estimate and actual costs from 25% to within 1-2%

Process 50 times more quotes than manual calculations

More accurate scrap estimates for material rebates

The cheapest layout, and hence cost, based on manufacturing constraints, as well as tooling costs

FEATURES:

Best in Class user interface - for immediate productivity

Multiple input formats - IGES, DXF (lines and arcs only)

Flexible setup - Optional pitch, coil width, and blank angle constraints to match available equipment and product requirements

Multiple Nesting layouts - Fully optimized one up, two up, and standard blank shape nesting layouts

Multi-Part Nesting - Two different parts that are manufactured together

Cost analysis - Accurate blank cost is calculated, accounting for the tooling costs

Interactive results - Sort results in an interactive spread sheet by material utilization, coil width, pitch, rotation angle and translation, including related nesting preview

Exporting - The current nesting layout can be exported in IGES or DXF format for use in other applications

Reports - Detailed reports showing the nesting layout and calculated results can be printed

Catalogs

blanknest

2 Pages

Other FTI Forming Technologies Incorporated products

FormingSuite

Related Searches

- Analysis software solution

- Process software solution

- Computer-aided design software

- Real-time software solution

- Design software solution

- Simulation software

- Development software

- Engineering software

- Calculation software

- CAD/CAM software

- SolidWorks software

- Nesting software

- PLM software

- CATIA V5 software

- Cost estimation software

- Schema design software

- Stamping simulation software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.