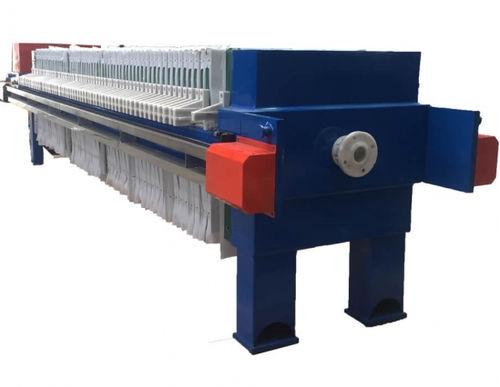

This filter press could be of automatic plate opening device and automatic water collector, which automatic open the plates one by one, automatic open and close the water collector.

Filter Press Characteristic:

1. - Strengthen polypropylene filter plates and flame are made through mold pressing.

2. - Adopt hydraulic pressing with the maximum pressure pressure of 25Mpa and automatic pressure maintaining by using electrical connecting pressure gauge.

3. - PLC control system, automatic open the plates one by one, open and close the water collector.

Filter Press Application:

Square filter plates are widely used in Food, Chemical, Dyeing, Leather, Mining (Aluminium, Bauxite, Copper, Iron) and Electroplate.

Filter Press Working:

The slurry is sent by slurry pump to chambers which formed by filter plates. Then filtrating media (filter cloth) separates solid and liquid. After the filtration finished, stopping the feeding, releasing the slurry pressure, press the returning button, shifting the plates automatically.