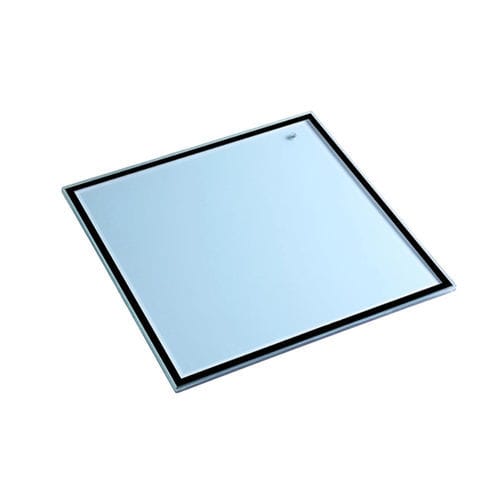

The main body consists of two pieces of glass stacked in parallel, in which supporting materials are placed at a certain distance. Welding materials are used around the glass for permanent sealing in a high vacuum environment. Polymer sealing materials are used around the core welding materials for structural strengthening and solder protection. High vacuum performance double sealed vacuum glass without air extraction port is obtained to meet the characteristics of heat insulation and sound insulation.

In order to improve heat insulation and adjust lighting performance, one piece of Low-E (low emissivity) coated glass would be used.

In order to balance the influence of gas penetration of glass itself and weld gas penetration on the service life of vacuum glass, alloy getter would be implanted in the vacuum chamber.

Longer Service Life

Vacuum leakage rate ≤10-12mbar.L/s, long life pursuit;

-50℃-100℃ use span, excellent environmental adaptability;

Using lead-free alloy solder with independent intellectual property rights, better fit with glass.

Better Thermal Insulation

The heat insulation performance of VIG vacuum glass is improved by 2-4 times than that of insulating glass;

VIG vacuum glass can save 56.3% energy than ordinary insulating glass.

Anti-condensation

Dew point temperature is well below -60℃, excellent frost resistance

Smart Manufacturing

VIG vacuum glass sealing is adopted self-owned intellectual property rights of double-path sealing technology. The inner layer is sealed with independent low temperature lead-free solder, and the outer layer is made of polymer materials to strengthen the structure and protect the inner layer.