- Industrial machines and equipment

- Mixing and Dosing

- Planetary mixer

- FÜLL Process Group

- Products

- Catalogs

- News & Trends

- Exhibitions

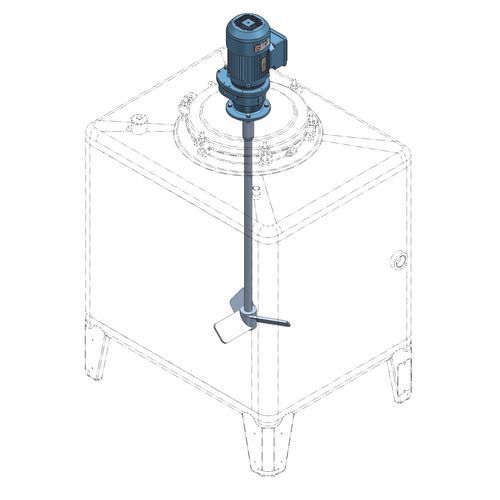

Planetary mixer batchsolid/liquid

Add to favorites

Compare this product

Characteristics

- Technology

- planetary

- Batch/continuous

- batch

- Product type

- solid/liquid

Description

Ich bin ein Textblock. Klicken Sie auf den Bearbeiten Button um diesen Text zu ändern. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Built-in agitators are agitators for installation from above onto a suitably dimensioned agitator nozzle or agitator flange. The agitators shown here are i.d.R. used for homogenizing, circulating and levitating. Agitators are a central component of the storage technology in most dosing systems. Here, agitators, in combination with a pipeline designed for circulation, ensure homogeneity of the raw materials and thus high quality during dosing. Subsequent QC measures (night sounds, etc.) are significantly reduced with the correct process engineering design of the storage system.

Barrel agitators are used for hobbocks, barrels, metal containers and other containers with lids. For this purpose, the provided lid of the container for receiving a stirrer is modified. The lid agitator is a top-mounted agitator, as it is designed for quick change and is simply placed on the container and locked. The advantage of these agitators is that they can be stirred directly in the delivery container. In storage systems of dosing systems, these agitators are used when no storage tank or storage container is available, in which the drum contents can be transferred or a circulation line does not ensure adequate mixing.

IBC agitators – also called container stirrers or traverse stirrers – are agitators that are installed on a carrier. These agitators belong to the group of top-mounted stirrers because they are only installed temporarily on an exchangeable container.

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Volumetric dosing unit

- Liquids dosing unit

- Automatic dosing unit

- Solid/liquid homogenizer

- Mixer-dispenser

- Dispensing valve

- Continuous dispensing system

- Gravimetric dosing unit

- Planetary mixer

- Dosing unit for the chemical industry

- High-precision mixing and metering unit

- Precision dispensing valve

- Batch blender for the plastics industry

- Liquids mixing and metering unit

- Automatic mixing and metering unit

- Laboratory dispensing system

- Mixer-dispenser for the food industry

- Needle dispensing valve

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.