- Industrial machines and equipment

- Surface Treatment Equipment

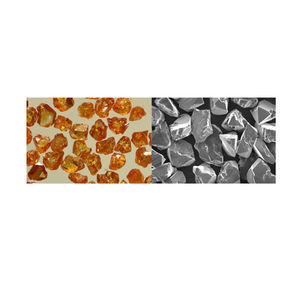

- CBN powder

- Funik Ultrahard Material Co., Ltd.

CBN powder CBN-900N55coatingabrasive

Add to favorites

Compare this product

Characteristics

- Material

- CBN

- Applications

- coating

- Other characteristics

- abrasive

Description

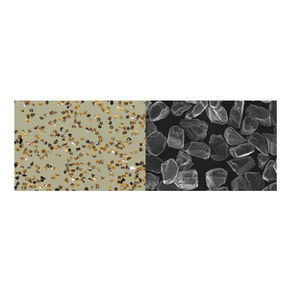

It is recognized that CBN (cubic boron nitride) is second only to diamond in hardness, two times that of diamond in high temperature resistance, four times that of traditional abrasive in wear resistance, and have extraordinary thermal conductivity. There are hundreds of raw materials needed to use CBN to grind in present manufacturing market, from aerospace superalloys and thermal spraying to the hardened steel in automotive bearing and gear industry to improve efficiency and get the shortest processing time.

Components and spare parts can get better quality by CBN grinding. Products are optimized to prevent thermal damage during the finishing process. At the same time, the quality consistency of the machined parts is improved. These machining technologies make full use of CBN advantages of increase grinding wheel life and wear reduction. So that the expensive machine can run longer time between the grinding tool replacements and reduce the adjustment time during operation to better meet the requirement of modern automated machine and improve productivity and work efficiency.

Adopting mature electroplating technology, abrasive is plated with different proportion of nickel, which can effectively improve grinding wheel life.

VIDEO

Catalogs

FUNIK CBN Powder CBN-900N55

4 Pages

Other Funik Ultrahard Material Co., Ltd. products

CBN/Diamond Superabrasive

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.