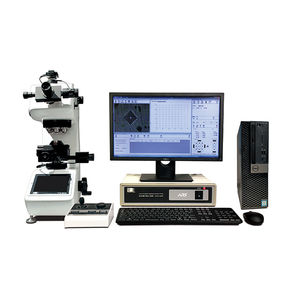

Vickers indentation hardness tester ARbenchtopfor load cellsautomatic

Add to favorites

Compare this product

Characteristics

- Type

- Vickers

- Mounting

- benchtop

- Product applications

- for load cells

- Other characteristics

- automatic

Description

Controlled by high performanace software FT-ZERO

・By combining with Hardness Tester, stage control is automated in indent/

multi-pointmeasurement to reduce the dispersion caused by each operator.

・This system is very effective for large-scale rationalization

and energy saving.

Features

■High resolution camera(Common to each model )

・Equipped with a 1.3M pixel high resolution digital camera.

■ Image processing software(Common to each model)

・Capability of reading unclear indents on un-mirror surface

has been improved by more advanced image processing software.

Various data output format and statistical processing(Common to each model )

・For the measuring of carburizing / induction hardening, the se lected hardness case depth shall be displayed and recorded

on the chart once the multiple measuring is completed.

・Multiple measuring data, Hardness chart, Case depth, Max. valu e, Min. value, Mean value, Dispersion, Standard deviation,

OK-NG criteria, Conversion data etc… various data output shal l be available.

・Display and output of color profile picture linked with hardne ss values are standard function.

・Excel data transfer function. Test result shall be exported to the original report Form.

AUTOMATIC INDENTATION MEASURING SYSTEM AR

• - Indentation measurement is automated!!

Light-and-dark image processing protects this system agaist the influence of metals or damage.

Automatic measurement can be done with high accurate repeatability exceeding any skilled technician.

Catalogs

Other FUTURE TECH products

LOAD-CELL VICKERS HARDNESS TESTER AUTOMATION SYSTEM

Related Searches

- Test machine

- Indentation hardness tester

- Material testing machine

- Automatic test machine

- PC-controllable testing machine

- Benchtop indentation hardness tester

- Digital hardness tester

- Rockwell indentation hardness tester

- Brinell indentation hardness tester

- Vickers indentation hardness tester

- Automatic indentation hardness tester

- Superficial indentation hardness tester

- Micro indentation hardness tester

- Knoop/Vickers hardness tester

- Floor-mounted hardness tester

- Hardness test machine

- Fully-automatic test machine

- Jominy testing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.