- Production Machines

- Other Manufacturing Equipment

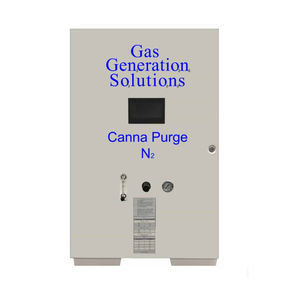

- Dry nitrogen generator

- Gas Generation Solutions

Injection molding nitrogen gas generator dry

Add to favorites

Compare this product

Characteristics

- Gas characteristics

- dry

- Domain

- for injection molding

Description

Nitrogen generators play a crucial role in plastic injection molding, acting as a propellant and protecting against moisture absorption in the resin. This process is widely known as Nitrogen Gas Assist Injection Molding and Film Extrusion, which is essential for various molding machines that typically require pressures ranging from 150 to 175 PSI.

Our Nitrogen Generators: Quality and Efficiency

Our nitrogen generators for plastic injection molding produce high-quality, dry nitrogen with a dewpoint of -40 degrees. This dewpoint is optimal for all types of injection molding processes. If your facility has additional air capacity, we can potentially utilize your existing air compressor to power the generator.

Invest in Our Systems for Long-term Savings

Investing in our nitrogen generator systems offers an average payback period of 12 to 14 months. We provide systems tailored to your specific needs, available in any purity, flow, and pressure configuration.

Sizing and Flow Measurement

We size nitrogen generators based on hourly flow and purity requirements. If your operation relies on high-pressure cylinders, we can estimate your flow based on operating hours.

Catalogs

No catalogs are available for this product.

See all of Gas Generation Solutions‘s catalogsOther Gas Generation Solutions products

NITROGEN GAS GENERATORS

Related Searches

- Nitrogen gas generator

- PSA nitrogen gas generator

- Laboratory nitrogen gas generator

- Pure nitrogen gas generator

- Compact nitrogen gas generator

- Process nitrogen gas generator

- Oxygen gas generator

- Industrial nitrogen gas generator

- LC/MS nitrogen gas generator

- UHP nitrogen generator

- Dry nitrogen gas generator

- Nitrogen gas generator on site

- Nitrogen generator for the food industry

- Laboratory oxygen generator

- Laser cutting nitrogen generator

- CMS nitrogen generator

- Medical oxygen concentrator

- Automatic nitrogen gas generator

- High-flow nitrogen gas generator

- High-pressure nitrogen gas generator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.