- Production Machines

- Other Manufacturing Equipment

- Nitrogen generator for the electronics industry

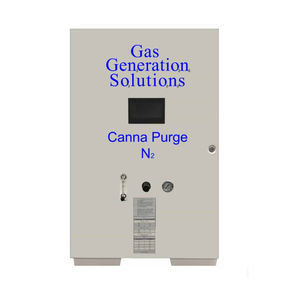

- Gas Generation Solutions

Nitrogen gas generator for the semiconductor industry high-purity

Add to favorites

Compare this product

Characteristics

- Gas characteristics

- high-purity

- Domain

- for the semiconductor industry

Description

How is a Nitrogen Generator used for semiconductor and silicon wafer manufacturing?

The four most significant usages for nitrogen in semiconductor and wafer manufacturing are Purging, Flushing, Deposition, and constant feed.

The surprising fact is that nitrogen is not used very much as an actual process gas in the fabricating of semiconductors. However, it is considered the essential gas used. This is in terms of the volume of nitrogen, the number of different applications, and the dollars spent per year to purchase. This is because nitrogen is used mainly as a purge gas. Semiconductor manufacturers use large volumes of nitrogen gas to purge process chambers, vacuum systems, waste abatement systems, and piping. Nitrogen generators are an ideal solution for all of the applications where the gas is required to manufacture semiconductors and silicon wafers. Our generators can produce large volumes of high purity gas at a low cost compared to delivered nitrogen.

Nitrogen Generators are the ideal alternative for companies looking to reduce their operation cost and are not on the underground pipeline. High purity nitrogen generators can have an average payback of 12 to 14 months. These systems have a typical lifespan of 15 to 20 years.

Catalogs

No catalogs are available for this product.

See all of Gas Generation Solutions‘s catalogsOther Gas Generation Solutions products

NITROGEN GAS GENERATORS

Related Searches

- Nitrogen gas generator

- PSA nitrogen gas generator

- Laboratory nitrogen gas generator

- Pure nitrogen gas generator

- Compact nitrogen gas generator

- Process nitrogen gas generator

- Oxygen gas generator

- Industrial nitrogen gas generator

- LC/MS nitrogen gas generator

- UHP nitrogen generator

- Dry nitrogen gas generator

- Nitrogen gas generator on site

- Nitrogen generator for the food industry

- Laboratory oxygen generator

- Laser cutting nitrogen generator

- CMS nitrogen generator

- Medical oxygen concentrator

- Automatic nitrogen gas generator

- High-flow nitrogen gas generator

- High-pressure nitrogen gas generator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.