- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

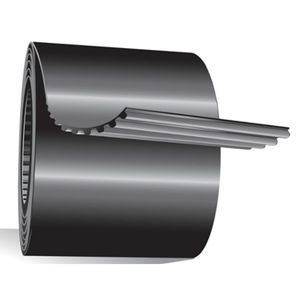

Synchronous belt POWERGRIP® GT®3 chloroprenemachine toolfor the textile industry

Add to favorites

Compare this product

Characteristics

- Type

- synchronous

- Material

- chloroprene

- Product applications

- machine tool

- Sector

- for the textile industry, for the paper industry

- Other characteristics

- high-resistance

- Width

3 mm, 6 mm, 9 mm, 15 mm, 25 mm

(0.118 in, 0.236 in, 0.354 in, 0.591 in, 0.984 in)- Pitch

Max.: 1,755 mm

(69.094 in)Min.: 100 mm

(3.937 in)

Description

PowerGrip® GT®3 belts are made of a highly advanced combination of materials designed to reduce both initial and operating costs. The entire PowerGrip® GT®3 belt range is suited both for new drive designs as for performance upgrades on existing drives. It has two times the rating of competitive RPP® belts and its predecessors PowerGrip® GT® and HTD®, with the largest selection of belts and sprockets in the industry. The 2MGT, 3MGT and 5MGT pitches are ideal for compact drives on hand tools, business machines, domestic appliances and high precision servomotor drives. The 8MGT and 14MGT pitches are the optimum choice for high performance drives in the machine tool, paper and textile industries where durability and low maintenance are required or to upgrade existing HTD® belt drive applications. At reduced widths, GT®3 belts can be used as a direct replacement for most 8mm and 14mm pitch standard rubber RPP® and HTD® synchronous belts.

FEATURES AND BENEFITS

Gates patented tooth profile is designed for use with a specific sprocket groove silhouette; sprocket groove-belt tooth combination increases capacity, while improving registration.

PowerGrip® GT®3 belts are available in 2, 3, 5, 8, and 14 mm pitch sizes. A single twist cord helps prevent the belt from moving downward on vertical shaft ACHE applications.

Technically advanced compound with fibreglass tensile cord, elastomeric teeth and backing and nylon facing.

Fibreglass tensile cord provides high strength, excellent flex life, and high resistance to elongation.

Elastomeric backing protects the cords from environmental pollution and frictional wear.

Catalogs

Preventive Maintenance Manual

92 Pages

Related Searches

- Gates transmission belt

- Flexible shaft coupling

- Shafts coupling

- Gates industrial belt

- Gates rubber belt

- Torque shaft coupling

- Gates plastic belt

- Backlash-free coupling

- Transmission shaft coupling

- Gates toothed belt

- Gates industrial belt

- Gates sturdy belt

- Engine shaft coupling

- Straight-toothed sprocket wheel

- Gates polyurethane belt

- Gates poly V belt

- Gates synchronous belt

- Flat strip

- High-torque shaft coupling

- Metal pulley

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.