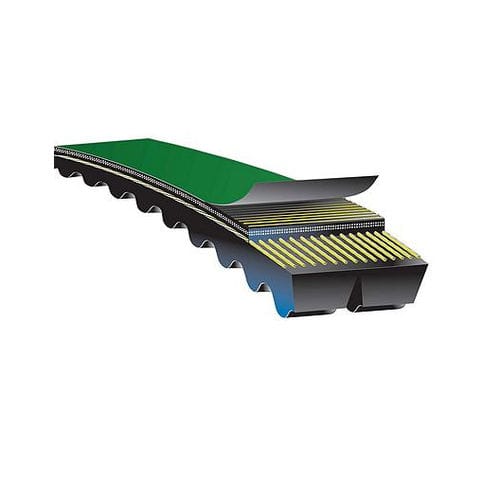

Trapezoidal power transmission belt Super HC® XP™ EPDM

Add to favorites

Compare this product

Characteristics

- Type

- trapezoidal

- Material

- EPDM

- Length

Max.: 5,081 mm

(200.04 in)Min.: 1,804 mm

(71.02 in)- Width

Max.: 104 mm

(4.094 in)Min.: 33 mm

(1.299 in)- Thickness

14 mm

(0.55 in)

Description

When your power transmission application needs a high horsepower solution but is constrained by drive weight or physical space, the answer is Super HC™ Molded Notch belts. Our proprietary ethylene construction process provides a superior combination of flex and load-carrying capacity, transmitting up to three times the horsepower versus comparably sized belts. Super HC MN V-belts put more power where high speeds, high speed ratios or small pulley diameters are required, offering significant benefits over classical section V-belts.

Flex-bonded tensile cords are vulcanized as one solid unit making the belt highly resistant to tensile and flexing forces, fatigue and shock loads.

Precision-ground straight sidewalls give a uniform wedging action and ensure the belt fits correctly in the pulley grooves, which improves belt life and reduces expensive maintenance time.

Patented Ethylene compound and optimized notches molded into the belt during manufacturing increase flexibility and transmission efficiency, which allows for a more compact and highly economical drive design by reducing size of pulleys, bearings, guards and mounts.

Recommended for use on all industrial heavy-duty, narrow section V-belt drives. All sizes meet Gates V80® system matching tolerances.

Meets ARPM/RMA IP-3-2 oil and heat resistant standards and IP-3-3 static conductivity requirements. REACH and RoHS 2 compliant.

Catalogs

GATES INDUSTRIAL POWER TRANSMISSION

302 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Power transmission belt

- Industrial power transmission belt

- Rubber power transmission belt

- Plastic strip

- Timing belt

- Industrial belt

- Sturdy belt

- V belt

- PU belt

- Straight-toothed sprocket wheel

- Synchronous power transmission belt

- Flat strip

- Metal pulley

- Oil-resistant power transmission belt

- Flexible belt

- Toothed pulley

- Pulley power transmission belt

- High-performance power transmission belt

- High-resistance power transmission belt

- Trapezoidal power transmission belt

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.