- Production Machines

- Cutting Machine

- Laser cutting machine

- GD HAN'S YUEMING LASER TECH CO.,LTD

- Products

- Catalogs

- News & Trends

- Exhibitions

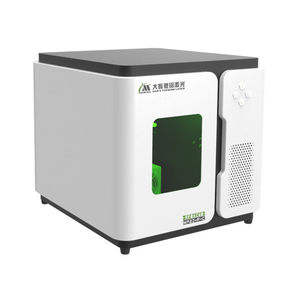

Label cutting machine FC300-B-Alaserfor metalfor plastics

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Material

- for metal, for plastics

- Product handled

- label

- Associated function

- marking

- Applications

- for industrial applications

- Workpiece loading

- automated loading/unloading

Description

Laser die-cut for Label Roll

Features

1.Roll to roll automatic loading and unloading, full or short of material automatic alarm, marking speed adjustable, long time running process without accumulated errors, automatic processing products.

2.Vision positioning process and sensor positioning process are optional without affecting the efficiency, marking accuracy can be improved to ±0.1mm.

3.The imported core components are optional, excellent performance, stable quality, long service life.

4.It adopts integrated design. Integrating machine hardware, control system and working platform, small footprint, and the whole machine is easy to operate.

5.Independently developed marking control software, powerful, friendly interface, simple and fast operation, easy to learn and use.

6.Strong compatibility: Support DXF, PLT vector and image format; Support dot matrix fonts and TTF fonts as well as self-developed fonts; Support two-dimensional code, pictures, characters and other content marking; Support a variety of galvo head correction; Greatly meet different levels of customer needs.

7.Multiple laser source optional: Support UV, fiber and CO2 laser source, suitable for metal, PE, cloth and other materials processing.

Technical Parameter

Model : FC300-B-A

Laser power(w) :

20-50(Fiber)

3-5(UV)

30(CO2)

Working area(mm) : Width of the coil 10~300

Overall dimension(mm) : 1450x770x1450

Weight(Kg) : 300

Speed(mm/s) : 0-7000

Supply voltage : AC220V/10A ±5%

Work environment : Temp:10~30°C, Humidity:5~85% ,Clean, less dust,

Total power(KW) : 2

Other GD HAN'S YUEMING LASER TECH CO.,LTD products

Laser Marking Machine

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Plastic cutting system

- Fabric cutting system

- Aluminum cutting system

- SS cutting machine

- Metal fabrication cutting system

- Cutting machine for the automotive industry

- CE cutting system

- High-performance cutting system

- Three-phase cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.