- Industrial machines and equipment

- Welding and Assembly

- Blocks of fat melter

- GD Process Design, LLC

Blocks of fat melter GDCR serieswith heat exchangerwith pump

Add to favorites

Compare this product

Characteristics

- Type

- for blocks of fat

- Other characteristics

- with heat exchanger, with pump

Description

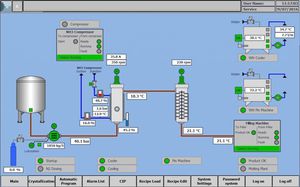

The GD Continuous Remelt Unit is delivered with either a Plate Heat Exchanger or a Shell & Tube Heat Exchanger. It comes complete with hot water makeup and circulation pump. All motors and electrical devices are wash-down enclosure. Transmitters and valves are pre-piped and pre-wired to a local mounted junction box. All units are delivered as a Plug-&-Play concept.

The CR-Unit is designed for continuous remelting of crystallized margarine. It is comprised of one section in the Plate Heat Exchanger (PHE) where the crystallized product is melted in a concurrent flow with hot water.

The CR-Unit is designed for cleaning in place (CIP) and consists of a PHE with one section for product, a water and steam regulating system with a soldered PHE for water tempering, water pump, valves and necessary piping.

Catalogs

No catalogs are available for this product.

See all of GD Process Design, LLC‘s catalogsOther GD Process Design, LLC products

GD Process Design Edible Oils and Fats

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.