Thickness measuring device MTT seriescorrosionmagnetic3D

Add to favorites

Compare this product

Characteristics

- Measured value

- thickness, corrosion

- Technology

- magnetic, 3D

Description

Detection and visualization

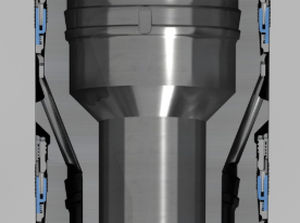

The Magnetic Thickness Tool (MTT) for corrosion evaluation and monitoring surveys variations in pipe metal thickness. It shows internal and external metal loss, detects pitting and gradual wall loss, and provides qualitative 3D images of well conditions.

MTT provides insight on piping and wall integrity

Depending upon the metal thickness of the casing wall through which it passes, an alternating emitted magnetic wave experiences differences in velocity and amplitude. These differences help detect and quantify variations such as pitting and metal loss. Data from BHGE’s Multi-finger Imaging Tool determines if the metal loss found by the MTT is internal or external.

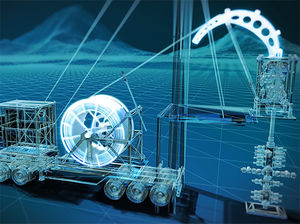

3D images created on a computer screen can be enhanced with color schemes, meshes, arrows and numerical data to help you better understand the structure and condition of your well.

MIT and MTT data automatically processed with WIPER software provides a joint-by-joint statistical analysis and creates a report summarizing the condition of pipe in the well.

Catalogs

No catalogs are available for this product.

See all of GE Compressors‘s catalogsRelated Searches

- Measuring device

- Geometry measuring device

- Measuring device with data logger

- Resistivity measuring device

- Diameter gauge

- Thickness measuring device

- Camera measuring device

- Surface measuring device

- 3D measuring device

- Magnetic measuring instrument

- Corrosion measuring device

- Concrete resistivity measuring instrument

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.