Gas turbine PGT25for power generationmechanical drivefor marine applications

Add to favorites

Compare this product

Characteristics

- Type

- gas

- Applications

- for power generation, mechanical drive, for marine applications

- Other characteristics

- aeroderivative, multi-stage, two-shaft, expansion, centrifugal

Description

The PGT25 is a simple cycle, two shaft gas turbine consisting of an LM2500 Aeroderivative gas generator coupled with a rugged, industrial power turbine.

Widely Referenced, Proven & Reliable Technology

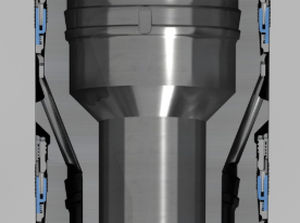

It leverages the best BHGE technology to respond to the demands of a gas turbine in the 23 MW range with high efficiency, reliability and availability, and low environmental impact. PGT25 can operate on a large range of both liquid and gas fuels. It is assembled on a rigid, lightweight base plate with extensive use of standard components, preassembled and tested in the shop to minimize on-site assembly time. Easy maintainability is one of the main features: the gas generator and low pressure turbine (cartridge) can both be easily and quickly removed and replaced, in order to minimize downtime.

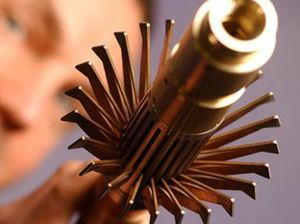

The LM2500 has accumulated several million fired hours in both aircraft engine and industrial applications (marine, onshore and offshore gas transmission) as mechanical drive and generator drive. It has a 16-stage axial-flow compressor capable of reaching an 18:1 pressure ratio. Inlet guide vanes and adjustable stator vanes on the first six compressor stages provide for efficient operation over the entire operating range.

The power turbine components are based on GE’s extensive experience with heavy-duty gas turbines and axial/centrifugal compressors. Aerodynamic blading obtains very high efficiency at both design and reduced speeds. The 6,500 RPM design speed means the turbine can have two stages with a moderate aerodynamic load and a high expansion efficiency. The two expansion stages have a high-energy, three-dimensional design.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.