- Hydraulics - Pneumatics

- Pump

- Piston pumping unit

- GE Compressors

Crude oil pumping unit Lufkin Gen 2pistonstationaryindustrial

Add to favorites

Compare this product

Characteristics

- Fluid

- for crude oil

- Technology

- piston

- Mobility

- stationary

- Domain

- industrial

Description

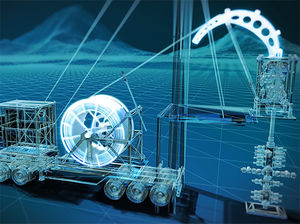

Enhanced components for safer, reliable operations

Our rod lift system portfolio includes a broad range of solutions—from low maintenance systems to the largest API sized units—to help meet operators’ efficiency and production goals.

Building on decades of experience in the oilfield and a long history of innovation in materials and design, today’s Lufkin Gen2 pumping units offer a superior production solution.

The units have been redesigned and standardized—making them safer and easier to install—while continuing to focus on providing reliable technology that enables operators to produce more efficiently and cost-effectively.

Practically every component of the Lufkin Gen2 pumping units has been enhanced for safety and efficiency. Design improvements include:

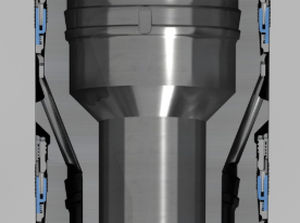

Load ratios of the structure bearings and crank pin bearings have been improved by an average of 27%, and 29% respectively.

Cranks and counterweights have been lengthened to achieve maximum counterbalance on a unit and lifting holes have been added to each for safer handling and installation.

Bottom-of-stroke ground clearance on the horse head increased as much as 12 in. on most models. This decreases the amount of foundation work needed by the operator and allows for more clearance between the carrier bar and top of the well head.

Super nuts added to all units, increasing torque reliability and seating of crank pins, and eliminating the need for a hammer when changing crank pins.

Catalogs

No catalogs are available for this product.

See all of GE Compressors‘s catalogsRelated Searches

- Pump

- Industrial pump

- Pump with electric motor

- Clear water pump

- Centrifugal pump

- Chemical pump

- Lubricant pump

- Transfer pump

- Chemistry pump

- Suction pump

- Lubricating oil pump

- Impeller pump

- Discharge pump

- Standard pump

- Top-mounted pump

- Vertical pump

- Process pump

- High-pressure pump

- High-efficiency pump

- Pump for oil industry applications

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.