- Products

- Catalogs

- News & Trends

- Exhibitions

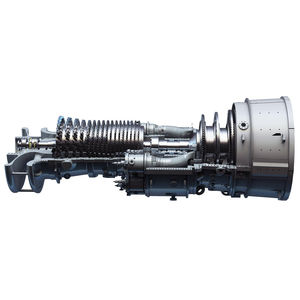

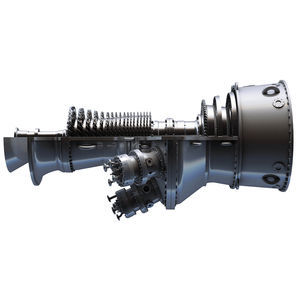

Gas turbine LM2500 seriesfor power generationmechanical drivecombined-cycle

Add to favorites

Compare this product

Characteristics

- Type

- gas

- Applications

- for power generation, mechanical drive

- Other characteristics

- combined-cycle, aeroderivative

- Rated power kW

Max.: 104,600 kW

(142,216.37 hp)Min.: 22,200 kW

(30,183.59 hp)- Efficiency

Max.: 55.1 %

Min.: 34.4 %

Description

The LM2500 family of aeroderivative gas turbines, including the LM2500XPRESS*, boasts several times the operating experience of its competitors combined, and its flexibility and reliability are unsurpassed.

The LM2500: Powerful and customizable

The LM2500’s high efficiency helps reduce operating costs, plant emissions, and reliance on the local grid. With its dual fuel capability, including singular annular combustor (SAC) or GE’s latest dual fuel dry low emissions (DLE) technology, the LM2500 delivers performance with low emissions in a variety of situations and water availability scenarios. It features high reliability with control system redundancy, along with multiple options for configuration, making it a great choice for customers who need a more tailored power generation solution. The LM2500’s cycling capability allows multiple daily starts and stops, providing a strong solution for grids with penetration of renewable generation. Its open configuration allows for faster accessibility, easier maintenance, and increased speed of engine removal/replacement.

Introducing the LM2500XPRESS: Modularity, reimagined

With up to 95% assembly in the factory, the LM2500XPRESS* was created for speed and simplicity. The LM2500XPRESS comes pre-packaged in 10 simplified modules for easy install and features 25 electrical interconnects vs. 130+ for a traditional plant, as well as minimal mechanical interconnects. Module systems flushing is completed at the factory, so customers don’t need to flush on-site. For customers who need power in days, not weeks, the LM2500XPRESS can be installed in about 14 days by 20 people.

VIDEO

Catalogs

Powering the world 2016

72 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.