The STF-D200 and STF-A200 non-reheat steam turbines are suited for a wide variety of applications, from pure power production to combined heat and power. Our steam turbines are highly flexible and engineered to meet specific customer applications.

Our 200 series steam turbines work well for combined-cycle conversion projects when a bottoming cycle is added to an existing simple-cycle plant to increase power output and efficiency upwards of 50 percent. Both the STF-D200 and STF-A200 are available with internally and externally controlled extractions to remove steam at any point along the steam path at the desired flow and pressure conditions. Our LP moisture removal features enable reliable operation and improve LP section efficiency, and a self-synchronizing clutch improves operational flexibility in a single-shaft configuration.

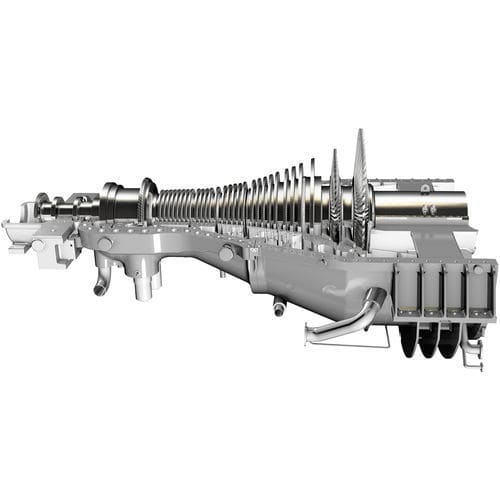

STF-A200

The STF-A200 steam turbine features a single casing configuration that ships fully assembled, enabling a four-month installation cycle from arrival on-site to turning gear operation; adaptive stage technology that controls low pressure extractions while intersections with valves are used for higher pressures; and many units (depending on machine size) are factory tested and pre-packaged to minimize installation and startup times.

STF-D200

The STF-200 steam turbine features a double flow LP section with available side exhaust that lowers the centerline for reduced plant costs, and the HP section is shipped fully assembled, enabling a five-month installation cycle from arrival on-site to turning gear operation.