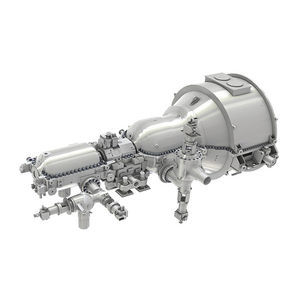

Steam turbine STF seriesfor power generationcombined-cyclesingle-shaft

Add to favorites

Compare this product

Characteristics

- Type

- steam

- Applications

- for power generation

- Other characteristics

- combined-cycle, single-shaft, single-casing

- Rated power kW

Max.: 340,000 kW

(462,271.19 hp)Min.: 70,000 kW

(95,173.48 hp)

Description

GE's two-casing dual LP flow STF-D200 steam turbine and single-casing, axial exhaust STF-A200 steam turbine work well for both 50 Hz and 60 Hz non-reheat applications in multi-shaft and single-shaft configurations.

Experience and features you can count on

The STF-D200 and STF-A200 non-reheat steam turbines are suited for a wide variety of applications, from pure power production to combined heat and power. Our steam turbines are highly flexible and engineered to meet specific customer applications.

Our 200 series steam turbines work well for combined-cycle conversion projects when a bottoming cycle is added to an existing simple-cycle plant to increase power output and efficiency upwards of 50 percent. Both the STF-D200 and STF-A200 are available with internally and externally controlled extractions to remove steam at any point along the steam path at the desired flow and pressure conditions. Our LP moisture removal features enable reliable operation and improve LP section efficiency, and a self-synchronizing clutch improves operational flexibility in a single-shaft configuration.

A closer look at our 200-series steam turbines

With more than 90 units deployed in the field since the late 1990s, the STF-A200 and STF-D200 have experience in both 50 and 60 Hz environments.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.