Volumetric feeder worm screwrotarypowder

Add to favorites

Compare this product

Characteristics

- Type

- volumetric, worm screw

- Operating mode

- rotary

- Product applications

- powder

Description

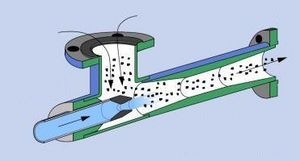

Volumetric feeding systems use an auger or screw conveyor running at a constant speed to discharge powder from a storage hopper at a consistent rate (volume per unit time - eg litres/min.) Frequently the hopper includes devices to condition the bulk material to ensure an even bulk density by using vibration, agitation, massaging, or other means to eliminate air pockets and maintain flow.

A wide variety of screw designs are used by GEA Nu-Con to suit each particular application:

Single Screw Twin Screw

Half Pitch Flighting Double Pitch Flighting

Open Flight Helixes Side/Top Discharge Nozzles

Polyethylene Helixes Variable Pitch Helix

Additional Options for mixing, stirring, spreading, and pulse elimination, and for handling difficult materials with special properties eg sticky, stringy, lumpy, aerated, cohesive, abrasive, dusty or fragile.

Specialised systems are also possible which do not use screws, such as vibratory feeders, rotary valve feeders, belt feeders and others.

For a Weighing System which is integrated into your overall plant design and control system contact GEA Nu-Con for an assessment of your requirements.

Catalogs

No catalogs are available for this product.

See all of GEA Colby‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.