- Industrial machines and equipment

- Heat Exchanger and Refrigeration

- Welded plate heat exchanger

- GEA Polacel Cooling Towers bv

- Products

- Catalogs

- News & Trends

- Exhibitions

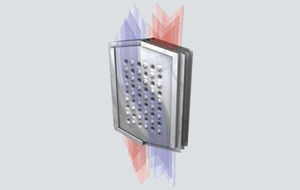

Welded plate heat exchanger GEABLOCair/airfor the petrochemical industry

Add to favorites

Compare this product

Characteristics

- Type

- welded plate

- Fluid

- air/air

- Applications

- for the petrochemical industry

- Operating pressure

35 bar

(507.63 psi)- Temperature

350 °C

(662 °F)

Description

GEABloc combines two different plate corrugations in an innovative way. The plates are rotated through 90° to one another and then welded together to produce two different cross-flow channels. The frame is made of four pillars, a bottom plate and a top plate together with four side pressure plates, and connections mounted in the pressure plates. All frame components are bolted together for easily dismantling to clean and maintain the plate pack.

GEABloc is available in various corrugation designs and sizes for a wide range of applications. Adjustable deflectors allow the heat exchanger to be adapted to its operating points delivering these features:

Max. operating temperature 315° C, on both sides

Max. operating pressure 32 bars, on both sides

Material 1.4404, SMO, Titanium, etc.

Surface area 1–320m²

Connection diameter DN50–DN400

Max. flow rate 3,860m³/h

Corrugation patterns: Herring-bone, Dimple

VIDEO

Catalogs

No catalogs are available for this product.

See all of GEA Polacel Cooling Towers bv‘s catalogsOther GEA Polacel Cooling Towers bv products

Fully welded plate heat exchangers

Related Searches

- Chiller

- Liquid chiller

- Heat exchanger unit

- Water chiller

- Air chiller

- Liquid/liquid heat exchanger

- Plate heat exchanger unit

- Compact chiller

- Tubular heat exchanger

- Stainless steel heat exchanger unit

- Gas/liquid heat exchanger unit

- Blast chiller for the food industry

- Steam generator

- Oil chiller

- Compact heat exchanger unit

- Brazed plate heat exchanger

- Shell and tube heat exchanger

- Condenser

- Gas/gas heat exchanger

- Air/water heat exchanger unit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.